Crack propagation in steel components presents significant challenges across critical engineering sectors including aerospace, automotive, and structural engineering. Component failures can lead to catastrophic damage, making accurate life prediction essential for safety and reliability.

Traditional experimental methods for studying crack growth are often prohibitively expensive and time-consuming. This is where advanced simulation techniques become invaluable. Our project demonstrates how the Extended Finite Element Method (XFEM) in Abaqus provides an efficient, accurate alternative for modeling crack growth in steel structures.

Download the complete Abaqus CAE file for this crack growth simulation – Available Now

Advanced Crack Growth Simulation with XFEM in Abaqus

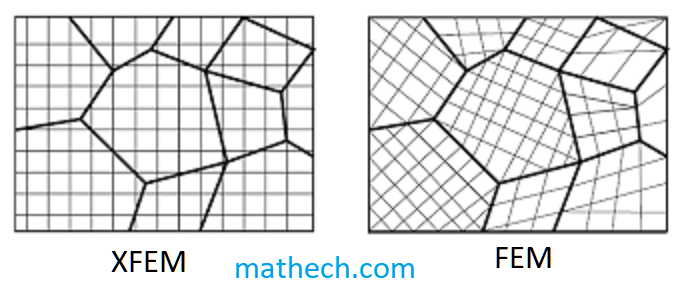

The Extended Finite Element Method (XFEM) represents a significant advancement in fracture mechanics simulation. This innovative approach enables cracks to propagate freely through finite elements without the computational overhead of traditional remeshing techniques.

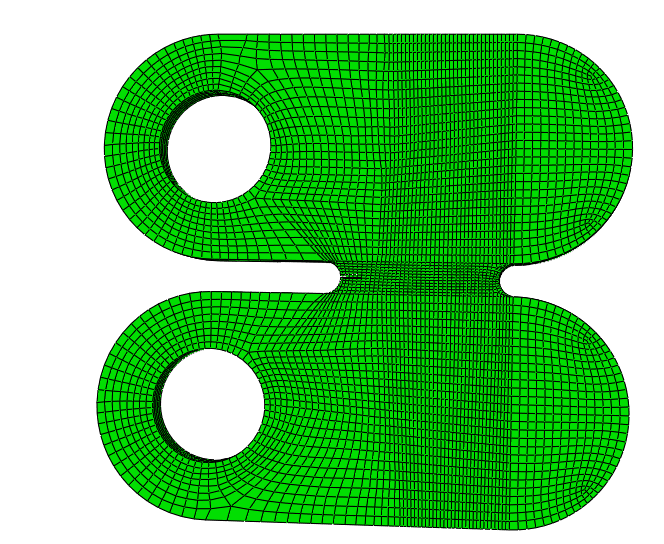

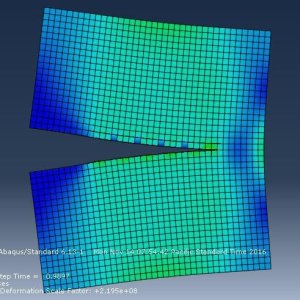

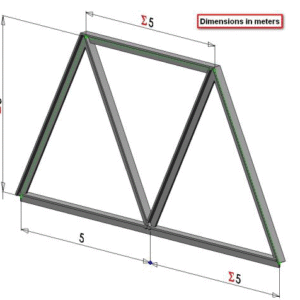

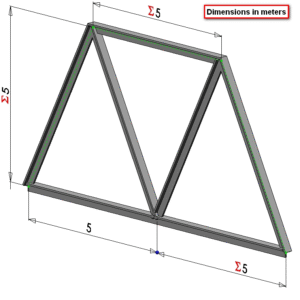

Visual comparison demonstrating XFEM’s ability to model crack propagation through elements versus traditional FEM requirements

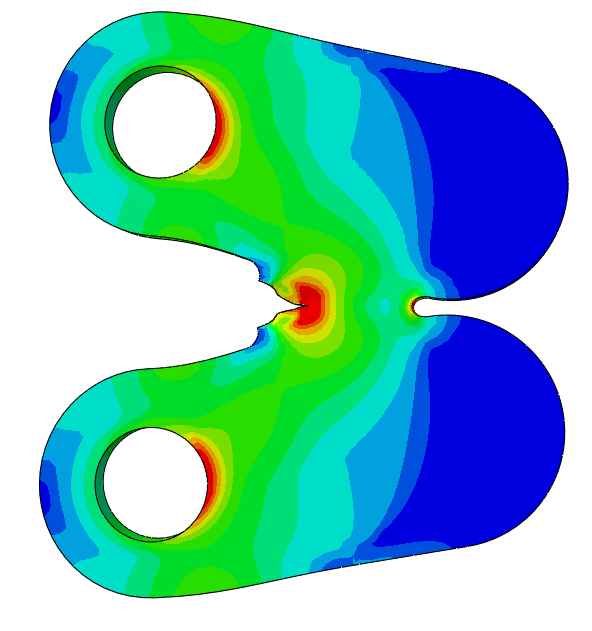

Our implementation in Abaqus/Standard incorporates fundamental fracture mechanics principles, including calculation of Stress Intensity Factors (SIF) and energy release rates. This enables comprehensive evaluation of crack behavior under both static and cyclic loading conditions.

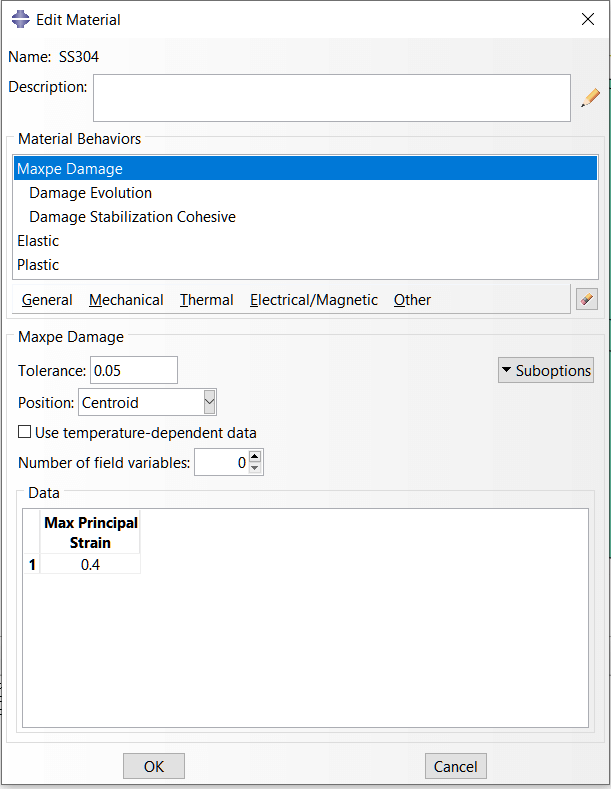

MaxPE Damage Model for Accurate Crack Prediction

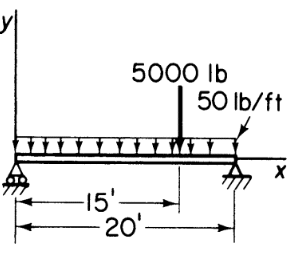

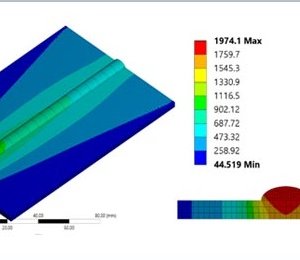

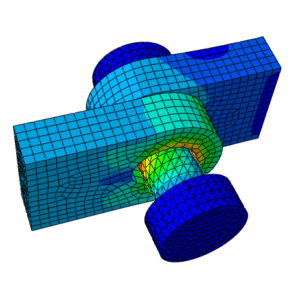

Material property configuration showing MaxPE damage model implementation for steel crack simulation

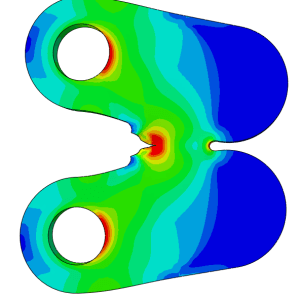

The MaxPE (Maximum Principal Strain) criterion integrated within Abaqus’ XFEM framework enables mesh-independent crack growth simulation. This advanced damage model provides several key advantages:

- Eliminates requirement for adaptive remeshing

- Accurately predicts complex crack paths in ductile materials

- Suitable for both static and fatigue loading analysis

- Enables reliable structural integrity assessment

Master Crack Growth Simulation

Go beyond the free file with our comprehensive step-by-step tutorial

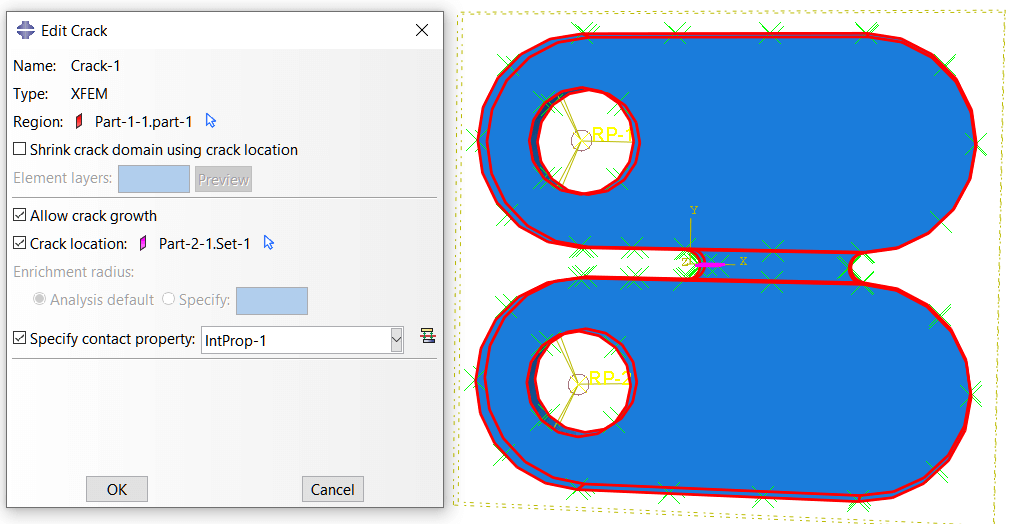

Defining Crack Interactions in Abaqus

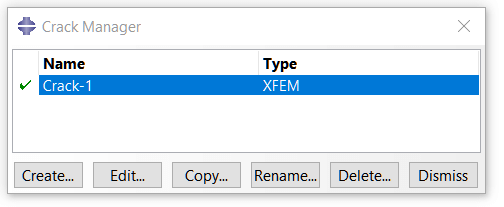

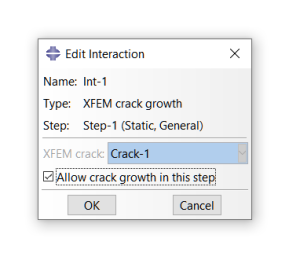

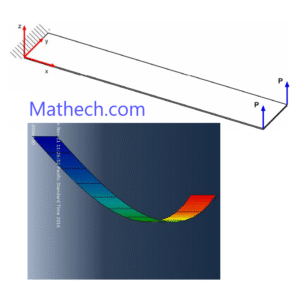

Abaqus provides specialized tools for comprehensive crack interaction analysis through its XFEM framework. The software enables detailed study of individual crack propagation behavior based on specific geometry and loading conditions.

The simulation workflow includes defining initial cracks, specifying material fracture properties, and establishing loading scenarios to analyze critical fracture mechanics parameters.

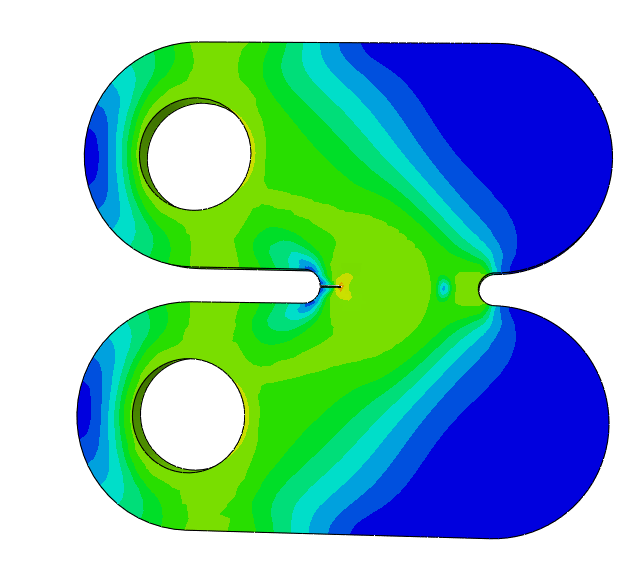

Complete XFEM simulation showing crack propagation and stress distribution

Interaction definition for enabling XFEM crack growth in analysis steps

This comprehensive approach makes Abaqus an indispensable tool for failure analysis and damage tolerance assessment across various engineering applications.

Frank –

As a mechanical engineer, I needed to simulate realistic crack propagation. The Abaqus CAE files provided with predefined cracks and step-by-step PDF instructions were invaluable.

Mathech Team –

Thank you so much Frank. We are preparing a new post about the growth of crack in Abaqus. Check our site again.

Mike T –

As a mechanical engineer, I needed to simulate realistic crack propagation. The Abaqus CAE files provided with predefined cracks and step-by-step PDF instructions were invaluable.