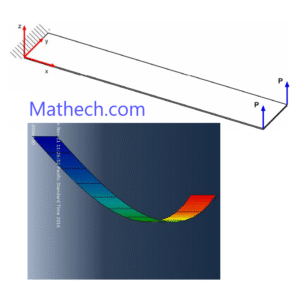

Learn how to simulate single-pass welding on a flat plate in

Abaqus using the birth and death technique for element activation

and a Fortran DEFLUX subroutine to model the moving heat source.

This step-by-step Abaqus guide is perfect for engineers and FEA analysts working on

welding process simulations.

Step 1: Abaqus Model Setup

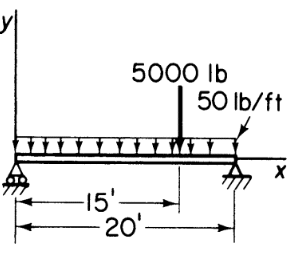

Prepare the base model in Abaqus/CAE for a realistic welding simulation.

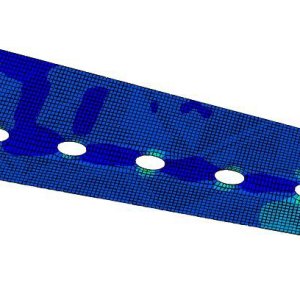

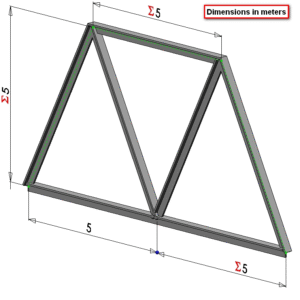

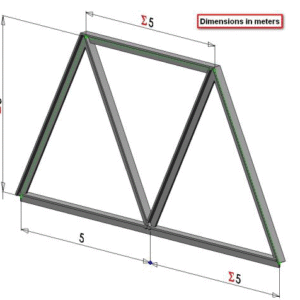

- Create a 3D deformable flat plate and define a separate weld bead section.

- Assign material properties such as density, conductivity, specific heat, and plasticity.

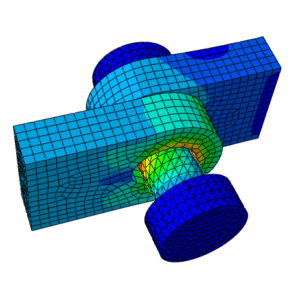

- Use C3D8T elements for coupled thermal-mechanical analysis and finer mesh near the weld zone.

Step 2: Implementing the Birth and Death Method

Abaqus does not directly support element birth and death, but you can activate or deactivate regions

using *Model Change commands.

- Deactivate weld elements initially with

*Model Change, Remove. - Activate elements step-by-step using

*Model Change, Add.

Step 3: Defining the Welding Heat Source (DEFLUX Subroutine)

Use a Fortran DEFLUX subroutine to define a moving Gaussian heat flux

that travels along the weld line. Below is an example structure:

SUBROUTINE DEFLUX(FILM,COORDS,JTEMP,TEMP,TIME,DTIME,NOEL,NPT,LAYER,KSPT)

INCLUDE 'ABA_PARAM.INC'

DOUBLE PRECISION FILM, COORDS(3), TEMP, TIME(2), DTIME

INTEGER NOEL, NPT, LAYER, KSPT, JTEMP

DOUBLE PRECISION Q, r, eta, V, A, r_max, x0

PARAMETER (Q=3000.0, eta=0.8, V=5.0, A=6.0)

x0 = V * TIME(1)

r = SQRT((COORDS(1)-x0)**2 + COORDS(2)**2)

r_max = 3.0

IF (r .LE. r_max) THEN

FILM = eta * Q * EXP(-3.0*(r**2)/(A**2))

ELSE

FILM = 0.0

ENDIF

RETURN

END

Step 4: Analysis Steps and Element Activation

Create sequential steps for heat input, cooling, and residual stress analysis.

** Step 1: Heat input

*HEAT TRANSFER, STEADY STATE

1.0, 100.0

*MODEL CHANGE, ADD

Weld_Pass1

Step 5: Running the Simulation

- Save and verify the model.

- Compile the DEFLUX subroutine using the Abaqus command line.

- Run:

abaqus job=welding user=deflux.for

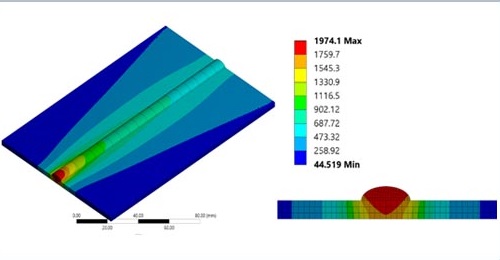

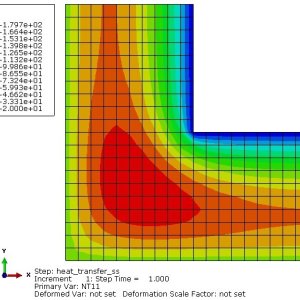

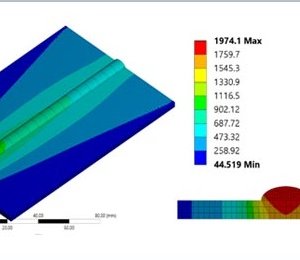

Step 6: Post-Processing and Results

- Visualize temperature distribution and thermal cycles.

- Check weld bead activation and residual stress fields.

This Abaqus welding tutorial demonstrates how to combine

element activation techniques and heat flux subroutines

for accurate FEA welding simulation.

Need Expert Help with Abaqus Welding Simulation?

Mathech provides FEA consulting, custom subroutine development, and Abaqus project support.

Lisa Wang –

Very practical tutorial for coupled temp-displacement analysis. The methodology for defining material properties that change with temperature was crucial for getting accurate distortion results. Great work.

David Mueller –

This tutorial filled a major gap in welding simulation resources. The explanation of modeling the filler material activation using model change was particularly valuable. Our analysis of welding distortion improved significantly.

Angela Roberts –

Outstanding guide for welding simulation. The section on visualizing the residual stress field and comparing it to experimental data was incredibly helpful. This has become a key reference for our team.