Disc brakes are critical to vehicle safety and performance. Under high-speed or emergency braking, these components undergo extreme thermal and mechanical stresses. Understanding how disc brakes respond to heat and stress is essential to avoid material failure, warping, or decreased braking efficiency.

This is where Abaqus, a powerful tool in Finite Element Method (FEM) simulation, becomes indispensable. Through advanced thermal-stress analysis in Abaqus, engineers can accurately simulate real-world braking scenarios and improve design robustness.

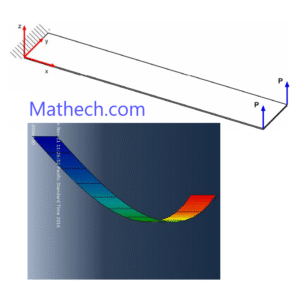

At Mathech.com, we specialize in Abaqus consulting services to help businesses and engineers carry out such high-fidelity simulations. Whether you’re developing disc brakes, analyzing failure modes, or optimizing performance, our expertise can give you a competitive edge.

What Is Thermal-Stress Analysis in Disc Brakes?

During braking, a vehicle’s kinetic energy is converted into heat due to friction between the brake pad and disc. This rapid heat generation leads to significant temperature gradients, causing the disc to expand non-uniformly. As the material expands and contracts during repeated braking cycles, thermal stresses develop, which can lead to:

Crack initiation and propagation

Brake fade or failure

Permanent deformation

Reduced braking efficiency

Thermal-stress analysis helps predict these issues early and validate whether a design can withstand repeated thermal cycling.

Why Use Abaqus for Disc Brake Simulation?

Abaqus is an industry-standard FEM software trusted by engineers worldwide for high-precision simulations. It offers:

Coupled temperature-displacement analysis

Transient thermal modeling

Nonlinear material behavior simulation

Advanced contact definitions

Support for rotating and symmetric components

These features make Abaqus ideal for simulating complex phenomena like brake disc heating, cooling, and the resulting mechanical stresses.

Need Help With Your Brake Disc Simulation?

Our experts can help you set up accurate thermal-stress simulations in Abaqus and interpret the results.

Simulation Workflow in Abaqus: Disc Brake Case Study

Inspired by a well-known tutorial from Simulia documentation, here’s a step-by-step approach for thermal-stress analysis of a disc brake using Abaqus:

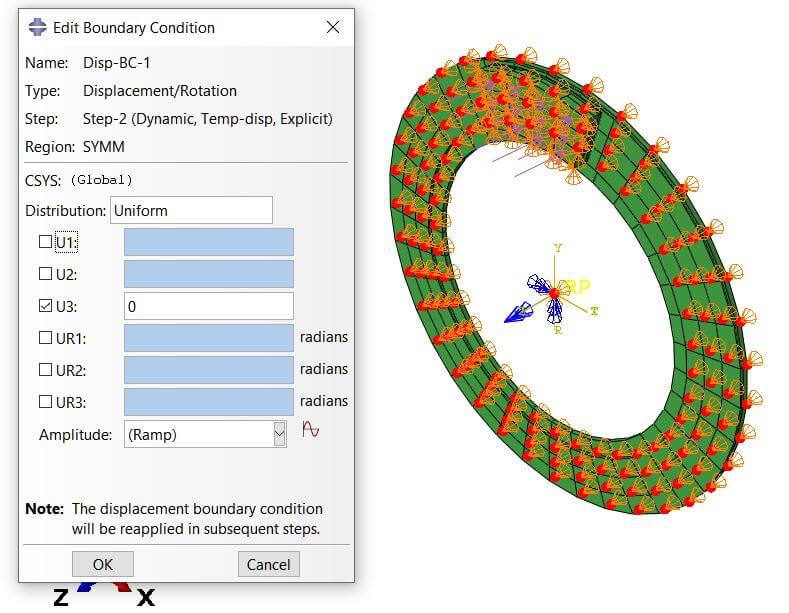

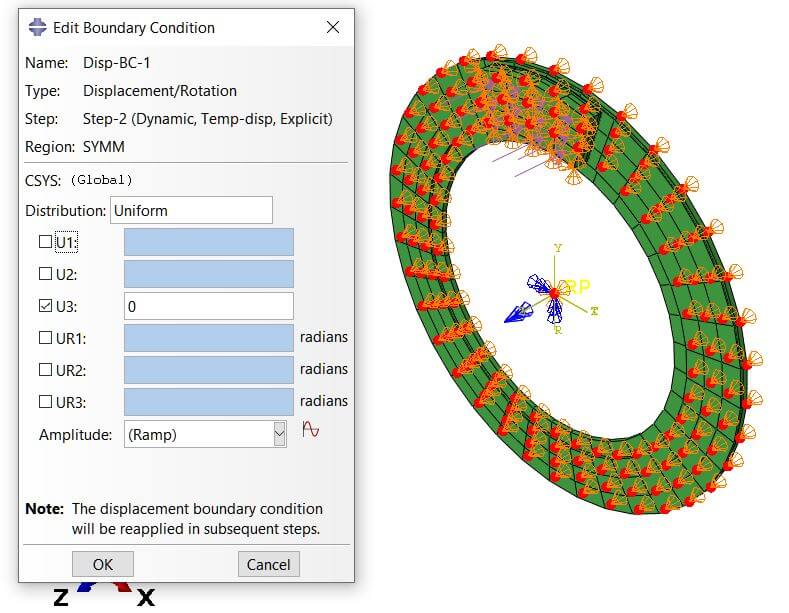

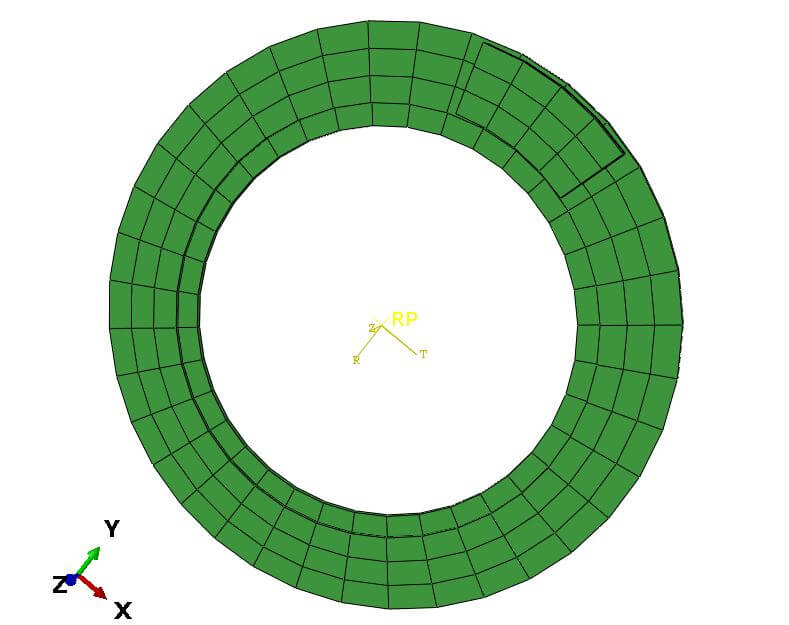

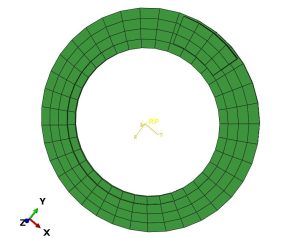

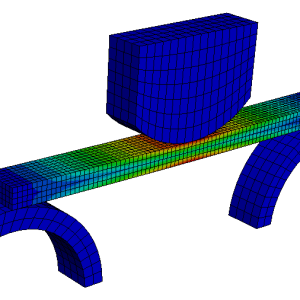

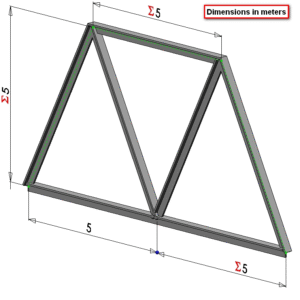

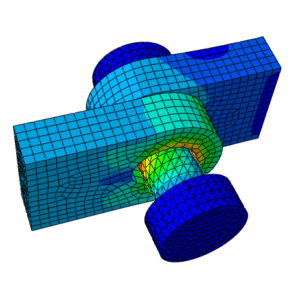

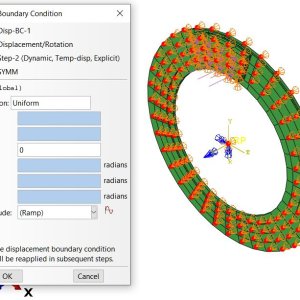

1. Geometry and Meshing

A 3D model of the brake disc is created.

Meshing is refined in high-gradient zones like near the inner and outer radii.

Symmetry is often used to reduce computation time.

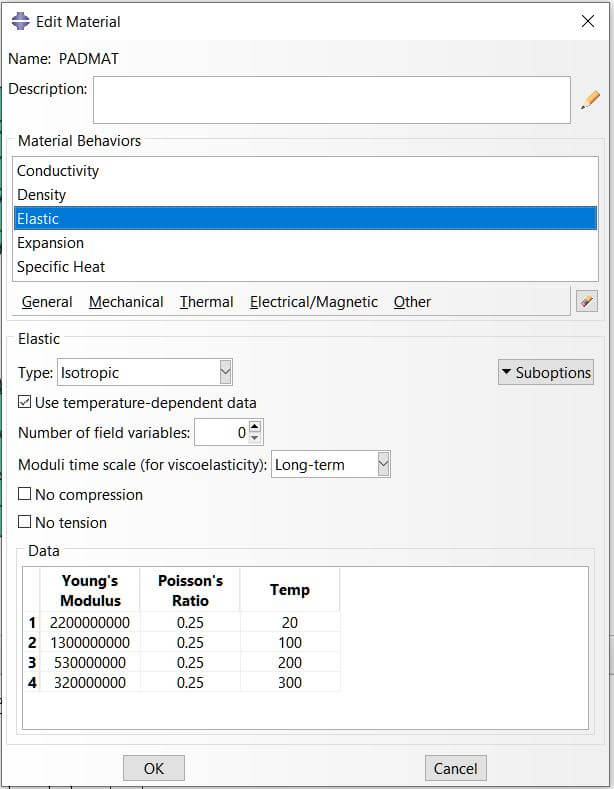

2. Material Definition

Cast iron or composite materials with temperature-dependent properties are defined.

Thermal conductivity, specific heat, and expansion coefficients are specified based on real-world data.

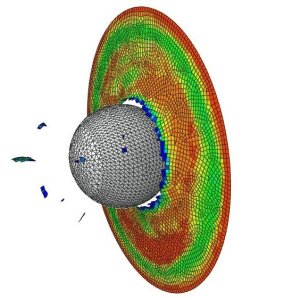

3. Thermal Analysis

A transient heat flux is applied to simulate braking over a defined period.

Convection boundary conditions simulate ambient cooling.

Abaqus/Standard or Abaqus/Explicit can be used depending on the level of detail needed.

4. Structural Analysis

The temperature field from the thermal step is imported.

Mechanical constraints (e.g., mounting bolts) are applied.

Abaqus calculates the resulting thermal stresses and deformations.

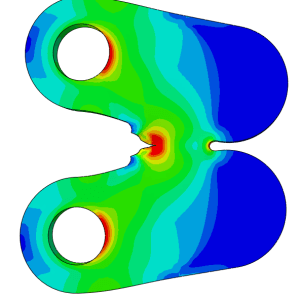

5. Post-Processing

Contour plots of stress and temperature are generated.

Critical regions prone to cracking or plastic deformation are identified.

Simulations can be repeated for multiple braking cycles or varied braking conditions.

Benefits of Abaqus-Based Simulation for Brake Systems

Early failure detection under high thermal loads

Faster design iteration compared to physical prototyping

Improved safety compliance

Cost-effective testing of materials and geometries

Optimization for weight and cooling efficiency

Outbound Resources

To dive deeper into advanced simulation techniques for brakes and thermal modeling, check out these expert resources:

FAQs About Disc Brake Thermal-Stress Simulation in Abaqus

❓ Why is thermal-stress analysis critical for disc brakes?

Thermal-stress analysis helps engineers predict how brake discs deform or crack due to heating and cooling. This is crucial for ensuring safety, especially in high-performance or heavy-duty vehicles.

❓ Can Abaqus simulate both thermal and mechanical behavior simultaneously?

Yes! Abaqus supports coupled temperature-displacement simulations, allowing accurate prediction of stresses resulting from temperature variations.

❓ What data is needed to simulate a brake disc accurately?

You’ll need:

3D geometry

Temperature-dependent material properties

Frictional heat input or braking energy

Cooling boundary conditions (like convection coefficients)

❓ Is simulation better than physical testing?

While physical testing is necessary for validation, simulation is more cost-effective and faster in the early design phase. It allows testing multiple scenarios without building prototypes.

❓ How can Mathech.com help?

We offer tailored FEM consulting using Abaqus, helping clients:

Set up realistic simulations

Interpret complex results

Optimize product designs Reach out to us here for a free initial assessment.

Conclusion

Disc brakes endure extreme thermal and mechanical stresses that must be analyzed to avoid failure. With Abaqus, you gain a powerful platform for conducting thermal-stress simulations that are both accurate and efficient.

At Mathech.com, our consulting services help clients unlock the full potential of Abaqus to design better, safer brake systems. Whether you’re in automotive, motorsport, or heavy machinery, our simulation solutions ensure your braking components perform under the most demanding conditions.

Ronald.F –

I have been using Abaqus for many years, but have been mostly self-taught. This tutorial filled in many of the gaps in my knowledge in the field. The instructor doesn’t just show me what to do, but also explains why the solver behaves.