In this tutorial we are going to set up a finite element analysis (FEA) model in Abaqus to capture the dynamic behavior, material response, and interaction between the steel ball and aluminum sheet . Below is a detailed, step-by-step guide to perform this simulation using Abaqus/CAE, assuming a basic familiarity with the software interface.

Step 1: Define the impact Problem

- Objective: Simulate a steel ball impacting an aluminum sheet to analyze deformation, stress, strain, and potential damage.

- Parameters:

- Steel Ball: Assume a spherical ball (e.g., 10 mm diameter, density 7800 kg/m³, elastic-plastic behavior).

- Aluminum Sheet: Assume a thin square sheet (e.g., 100 mm x 100 mm x 2 mm, density 2700 kg/m³, elastic-plastic behavior).

- Impact Conditions: Initial velocity of the ball (e.g., 10 m/s downward).

- Material Properties:

- Steel: Young’s modulus = 210 GPa, Poisson’s ratio = 0.3, yield stress = 300 MPa, plastic hardening data (optional).

- Aluminum: Young’s modulus = 70 GPa, Poisson’s ratio = 0.33, yield stress = 100 MPa, plastic hardening data (optional).

- Analysis Type: Dynamic, explicit (suitable for high-speed impact).

Step 2: Create the Geometry in Abaqus

- Open Abaqus/CAE and create a new model database.

- Set Units: Abaqus is unitless, but ensure consistency (e.g., mm for length, kg for mass, s for time, N for force, MPa for stress).

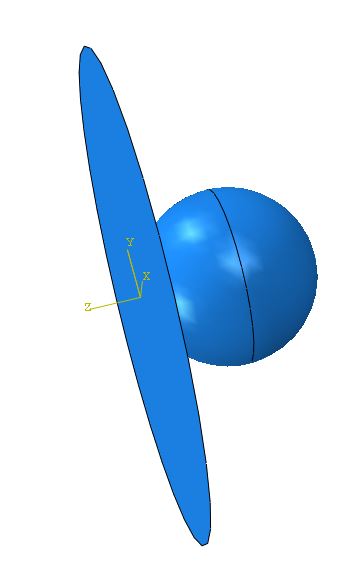

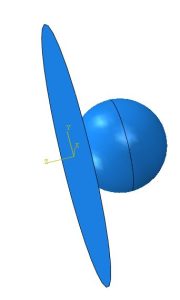

- Create the Steel Ball:

- Go to the Part module.

- Create a new part: 3D, Deformable, Solid, Revolution.

- Sketch a semi-circle (radius = 5 mm) in the XY-plane, with the center at (0,0), and revolve it 360° around the Y-axis to form a sphere.

- Name the part (e.g., “Steel_Ball”).

- Create the Aluminum Sheet:

- Create another part: 3D, Deformable, Solid, Extrusion.

- Sketch a square (100 mm x 100 mm) in the XY-plane.

- Extrude it to a thickness of 2 mm along the Z-axis.

- Name the part (e.g., “Al_Sheet”).

- Position the Parts:

- Ensure the ball is positioned above the sheet’s center. For example, place the ball’s center at (0, 0, 7 mm) so its bottom is 5 mm above the sheet’s top surface (Z = 0 to 2 mm).

Step 3: Define Material Properties

- Go to the Property module.

- Create Materials:

- Steel:

- Name: “Steel”.

- Mechanical → Elasticity → Elastic: Young’s modulus = 210e3 MPa, Poisson’s ratio = 0.3.

- Mechanical → Plasticity → Plastic: Enter yield stress (300 MPa) and plastic strain (0). Add hardening data if available (e.g., stress vs. plastic strain curve).

- General → Density: 7.8e-9 kg/mm³ (7800 kg/m³).

- Aluminum:

- Name: “Aluminum”.

- Mechanical → Elasticity → Elastic: Young’s modulus = 70e3 MPa, Poisson’s ratio = 0.33.

- Mechanical → Plasticity → Plastic: Yield stress = 100 MPa, plastic strain = 0. Add hardening data if desired.

- General → Density: 2.7e-9 kg/mm³ (2700 kg/m³).

- Aluminum:

- Steel:

- Assign Section Properties:

- Create a Section for each part (e.g., “Steel_Section” and “Al_Section”).

- Assign the respective materials (“Steel” to the ball, “Aluminum” to the sheet).

- Assign sections to the parts: Select the entire geometry of each part in the Assign Section tool.

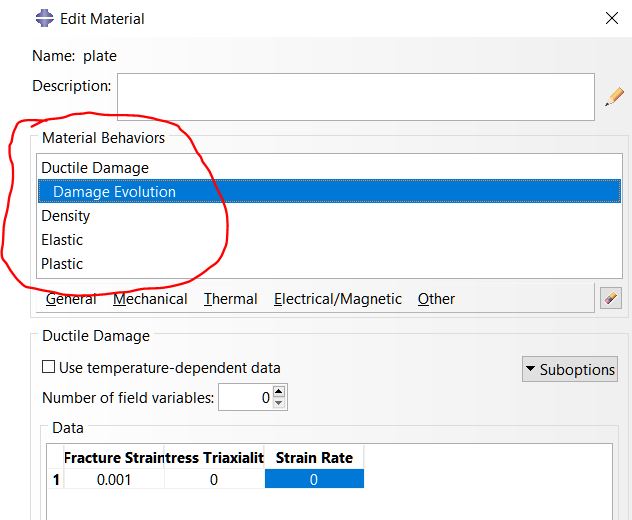

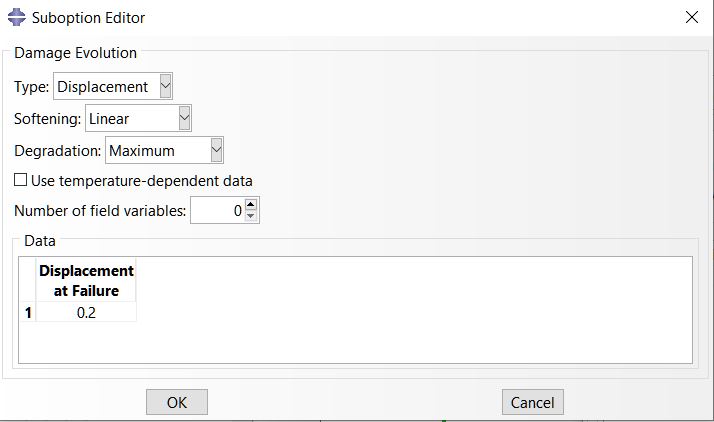

In the Ductile Damage Suboptions specify a damage evolution with a failure displacement of 0.2

In the Ductile Damage Suboptions specify a damage evolution with a failure displacement of 0.2

The damage evolution states that once the elements reach the failure criteria, i.e. a displacement of 0.2, then the element is deleted.

The damage evolution states that once the elements reach the failure criteria, i.e. a displacement of 0.2, then the element is deleted.

Create a section for each material and apply them to the geometry

o Ball

▪ Solid, homogenous

▪ Ball component

o Plate

▪ Shell, homogenous

▪ Shell thickness: 1

▪ Plate component

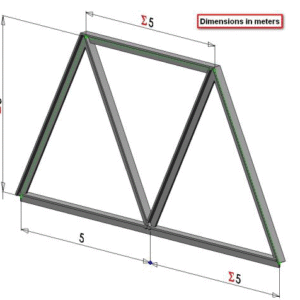

Step 4: Assemble the Parts for impact simulation

- Go to the Assembly module.

- Create Instances:

- Instance the “Steel_Ball” and “Al_Sheet” parts.

- Ensure the ball is positioned above the sheet as defined (e.g., ball center at Z = 7 mm, sheet top at Z = 2 mm).

- Verify Positioning:

- Use the Translate or Position tools to confirm the ball is centered above the sheet and offset vertically to avoid initial penetration.

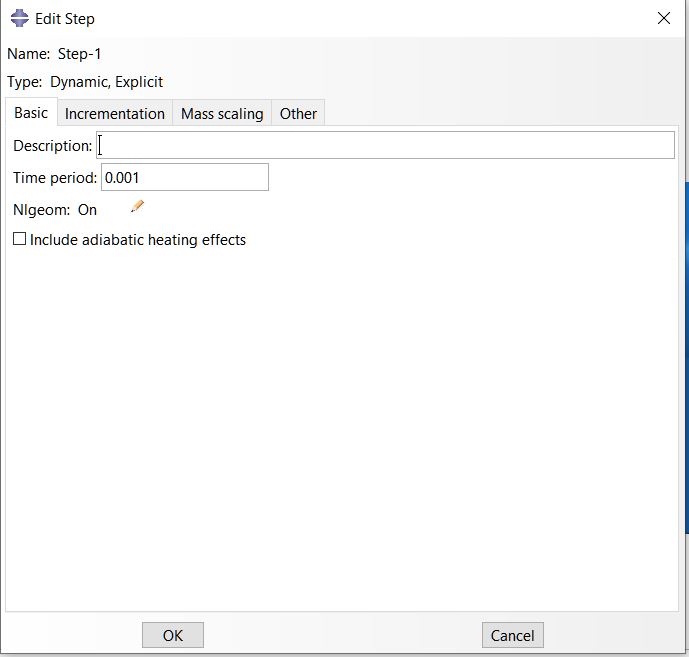

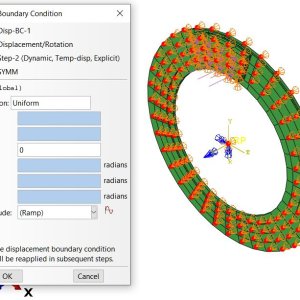

Step 5: Define the Impact Analysis Step

- Go to the Step module.

- Create a Step:

- Create a new step after the initial step: Dynamic, Explicit.

- Name: “Impact_Step”.

- Time Period: Estimate the impact duration (e.g., 0.001 s for a high-speed impact). For a 10 m/s impact over a small distance, 0.001 s is reasonable.

- Settings:

- Enable NLgeom (geometric nonlinearity) to account for large deformations.

- Set Time Incrementation to automatic for stability.

- Output Requests:

- Request field outputs: Stress (S), Strain (PE, LE), Displacement (U), Velocity (V).

- Request history outputs: Kinetic energy (ALLKE), Internal energy (ALLIE), Reaction forces (RF) at boundaries.

- Set output frequency to capture sufficient data (e.g., every 50 increments or 0.00001 s).

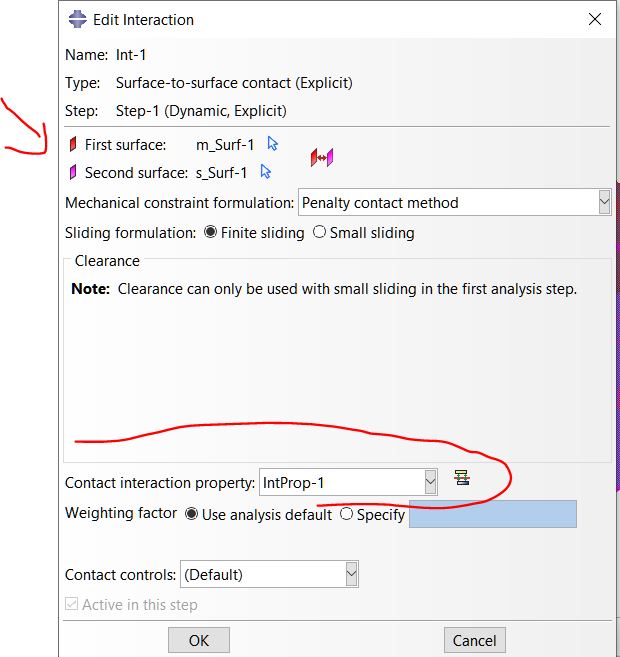

Step 6: Define Impact Interactions in Abaqus

- Go to the Interaction module.

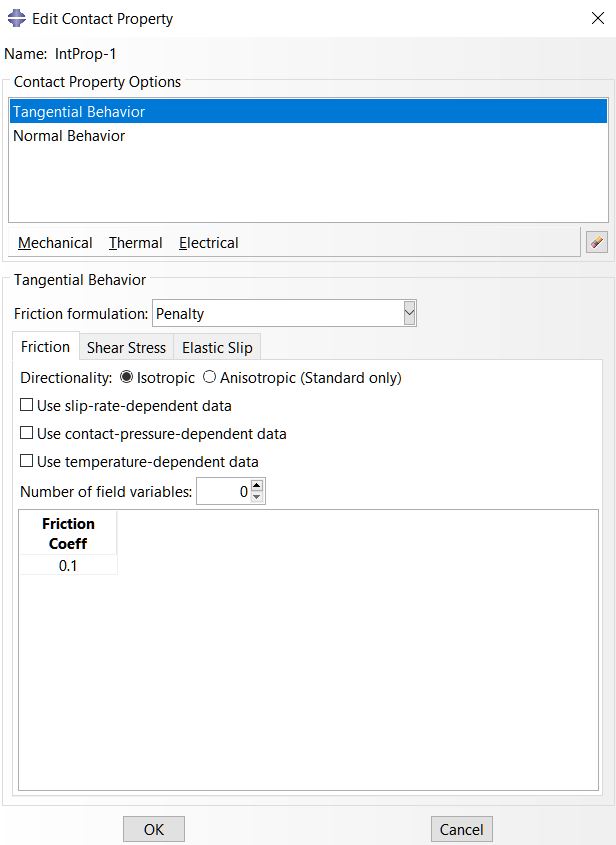

- Contact Properties:

- Create a Contact Property: Name (e.g., “Ball_Sheet_Contact”).

- Mechanical → Tangential Behavior: Friction coefficient (e.g., 0.2 for steel on aluminum).

- Mechanical → Normal Behavior: Hard contact, allow separation after contact.

- General Contact (Explicit):

- Create an Interaction: Select General Contact (Explicit).

- Assign the contact property (“Ball_Sheet_Contact”) to all surfaces.

- Include all part instances (ball and sheet) in the contact domain to account for self-contact if the sheet deforms significantly.

- Alternative (Surface-to-Surface Contact):

- If general contact is too computationally expensive, define a Surface-to-Surface Contact:

- Master Surface: Steel ball surface (more rigid, smaller contact area).

- Slave Surface: Top face of the aluminum sheet.

- Assign the contact property.

- Note: General contact is preferred for simplicity and robustness in explicit dynamics.

- If general contact is too computationally expensive, define a Surface-to-Surface Contact:

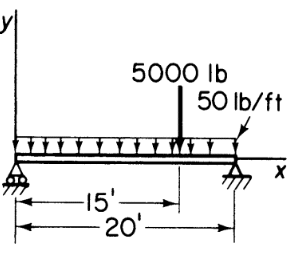

Step 7: Apply Boundary Conditions and Loads for impact

- Go to the Load module.

- Boundary Conditions for the Sheet:

- Create a Boundary Condition in the Initial Step.

- Name: “Fix_Edges”.

- Select the outer edges or perimeter of the sheet (e.g., all four sides).

- Apply: U1 = U2 = U3 = 0 (fix translation in X, Y, Z) to simulate clamped edges. Alternatively, fix only the bottom face or corners depending on the physical setup.

- Initial Velocity for the Ball:

- Create a Predefined Field in the Initial Step.

- Select Velocity.

- Select the entire steel ball.

- Set: V3 = -10,000 mm/s (downward, assuming Z is up). V1 = V2 = 0.

- Note: Do not apply velocity in the “Impact_Step” to avoid overriding the initial condition.

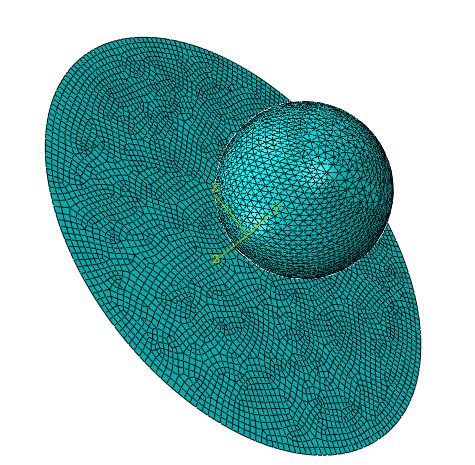

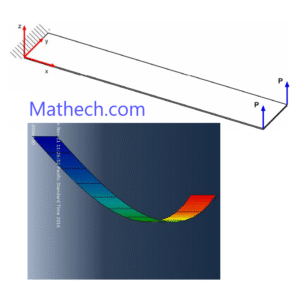

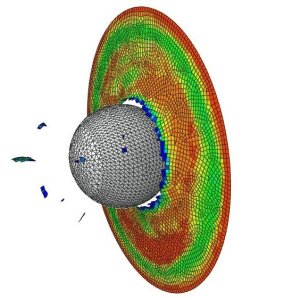

Step 8: Mesh the Model

- Go to the Mesh module.

- Seed the Parts:

- Steel Ball:

- Global seed size: ~0.5 mm (fine mesh for accuracy in contact and deformation).

- Local seed near the contact region (bottom of the ball): ~0.2 mm for higher resolution.

- Aluminum Sheet:

- Global seed size: ~2 mm.

- Local seed in the central impact zone (e.g., 20 mm x 20 mm area): ~0.5 mm to capture deformation gradients.

- Steel Ball:

- Element Type:

- Steel Ball: C3D8R (3D, 8-node linear brick, reduced integration, hourglass control) for solid elements.

- Aluminum Sheet: C3D8R for solid elements. If the sheet is very thin, consider S4R (4-node shell elements) with 5 integration points through thickness, but solid elements are better for impact.

- Mesh the Parts:

- Mesh both parts using Structured or Free meshing techniques.

- Ensure a refined mesh in the contact zone to improve accuracy.

- Verify mesh quality (no distorted elements) using the Query tool.

See more: How to Mesh a 3D Model in Abaqus: A Step-by-Step Guide

Step 9: Create and Submit the Job

- Go to the Job module.

- Create a Job:

- Name: “Ball_Impact_Simulation”.

- Select the model.

- Job Settings:

- Set Precision: Single or Double, depending on your system (Single is usually sufficient for explicit).

- Allocate sufficient memory and CPUs if available (e.g., 4 CPUs for faster computation).

- Submit the Job:

- Click Submit to run the analysis.

- Monitor the job in the Job Monitor for errors (e.g., excessive element distortion, contact issues).

- Debugging Tips:

- If the job aborts due to element distortion, refine the mesh or add Adaptive Meshing (ALE) in the Step module.

- If contact issues arise, check surface definitions or reduce the friction coefficient.

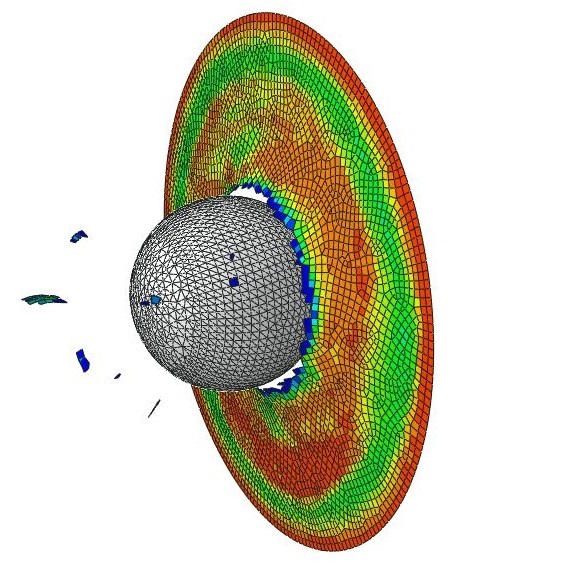

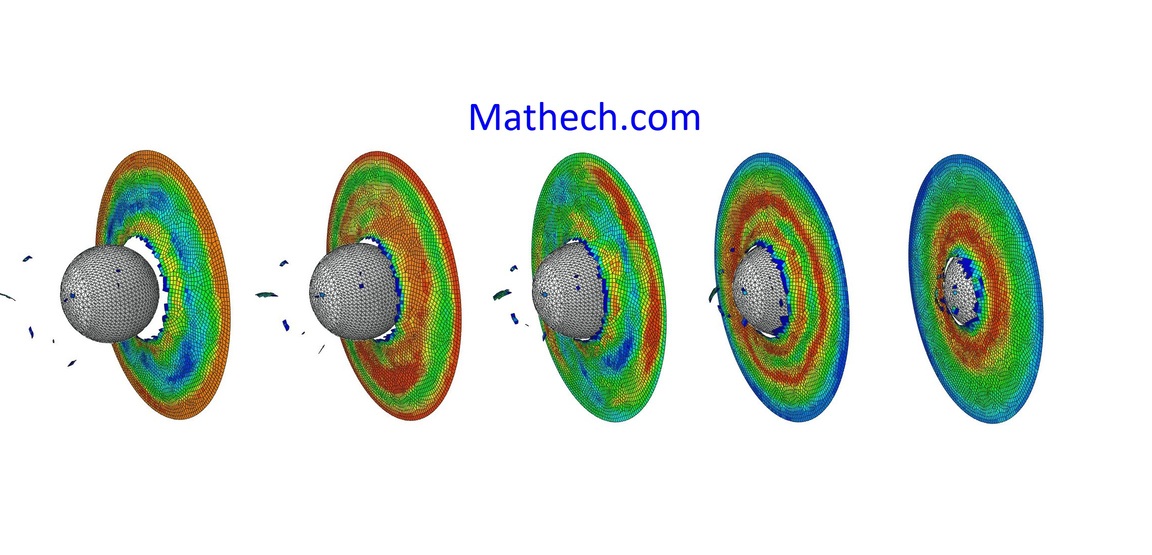

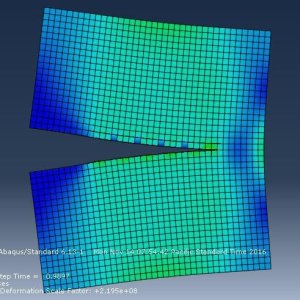

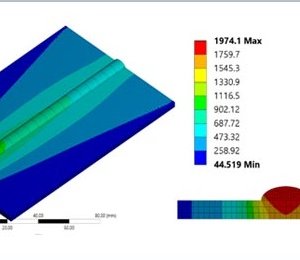

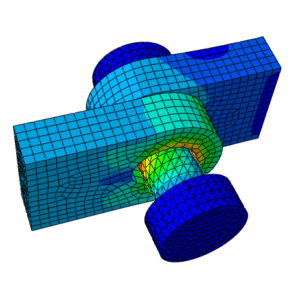

Step 10: Post-Processing and Analysis

- Go to the Visualization module.

- Open the Output Database (.odb file).

- Visualize Results:

- Displacement (U): Plot the deformation of the sheet (e.g., U3 for Z-displacement) to see the dent depth.

- Stress (S): Plot von Mises stress (S, Mises) to identify high-stress regions.

- Strain (PE): Plot plastic strain (PE, PEQM) to assess permanent deformation.

- Velocity (V): Check the ball’s velocity to confirm it slows upon impact.

- Energy Outputs:

- Plot ALLKE (kinetic energy) to verify energy transfer to the sheet.

- Plot ALLIE (internal energy) to check energy absorption.

- Ensure energy balance: Total energy (ALLKE + ALLIE) should remain nearly constant.

- Create Contour Plots:

- Use Contour plots to visualize stress/strain distribution on the sheet.

- Section the sheet to view internal stresses if needed.

- Extract Quantitative Data:

- Use Probe to measure maximum displacement, stress, or strain at the impact point.

- Create XY Data plots for energy histories (e.g., kinetic vs. time).

- Validate Results:

- Compare maximum deformation or stress with analytical estimates (e.g., Hertzian contact theory for elastic impact).

- Check for unrealistic results (e.g., excessive penetration, negative energies).

Step 11: Optional Enhancements for impact simulation in Abaqus

- Damage Modeling in Abaqus:

- Add Ductile Damage for aluminum in the Material definition to simulate fracture:

- Define damage initiation (e.g., equivalent plastic strain at onset).

- Define damage evolution (e.g., softening behavior).

- Enable Element Deletion to remove failed elements.

- This allows modeling of perforation if the impact energy is high.

- Add Ductile Damage for aluminum in the Material definition to simulate fracture:

- Rigid Body Approximation:

- If the steel ball deforms minimally, model it as a Rigid Body:

- In the Part module, set the ball as Rigid instead of Deformable.

- Assign a Reference Point at the ball’s center and apply mass (e.g., 0.032 kg for a 10 mm diameter steel ball) and velocity to the reference point.

- This reduces computation time but ignores ball deformation.

- If the steel ball deforms minimally, model it as a Rigid Body:

- Adaptive Meshing:

- Enable Adaptive Meshing in the Step module for the sheet to handle large deformations without element distortion.

- Use ALE Adaptive Mesh Domain and set remeshing sweeps (e.g., 10 per increment).

- Refine Contact:

- Add Contact Stabilization in the Interaction properties to prevent initial oscillations.

- Use a small damping factor (e.g., 0.0001) to stabilize without affecting results.

- Damage Modeling in Abaqus:

Step 12: Save and Document

- Save the Model: Save the .cae and .odb files for future reference.

- Document Results:

- Export plots (e.g., stress contours, energy curves) as images or data files.

- Note key findings: Maximum deformation, peak stress, energy transfer.

- Report Assumptions:

- Document simplifications (e.g., no strain-rate effects, no damage unless modeled).

- Mention mesh size, contact settings, and boundary conditions for reproducibility.

Here are some useful links for further reading on simulating impact in Abaqus, focusing on tutorials, documentation, and practical examples:

- Simulia Abaqus Documentation

- Simulia Products

- Description: Official Abaqus documentation covering explicit dynamics, contact modeling, and impact simulations. Access through your Abaqus installation or institutional subscription (Help → Documentation).

- CAE Assistant: High-Velocity Impact Simulation

- High-Velocity Impact in Abaqus

- Description: Tutorials on high-velocity impact simulations, including projectile impacts on various materials using Abaqus/Explicit.

- HyperLyceum: Abaqus Impact Simulation Tutorials

- Impact Simulation Part 1

- Description: Part of a seven-part series with detailed tutorials on impact modeling, covering scenarios like projectile impacts and fluid-structure interactions.

- Simuleon: Abaqus Tutorials

- Abaqus Non-Linear FEA Tutorials

- Description: Includes tutorials on crash and impact simulations, such as a ball impacting an aluminum plate, with practical Abaqus/Explicit examples.

- ResearchGate: Impact Simulation Discussions

- Abaqus Impact Load Simulation

- Description: Community discussions on impact load simulations, offering practical tips and troubleshooting advice.

Contact our consulting team.

Mark Jenkins –

Could you show how to extract the impact force data over time?

James Wallace –

Excellent tutorial. It saved me a lot of time. Please do more on explicit dynamics like this.

Sarah Chen –

This was very helpful! A follow-up on modeling different material models for the ball would be great.

David Miller –

Clear and easy to follow. Is there a way to estimate the plastic deformation in the plate after impact?

Emily Rodriguez –

Thanks for this! I’d love to see a part 2 that includes thermal effects from the impact.