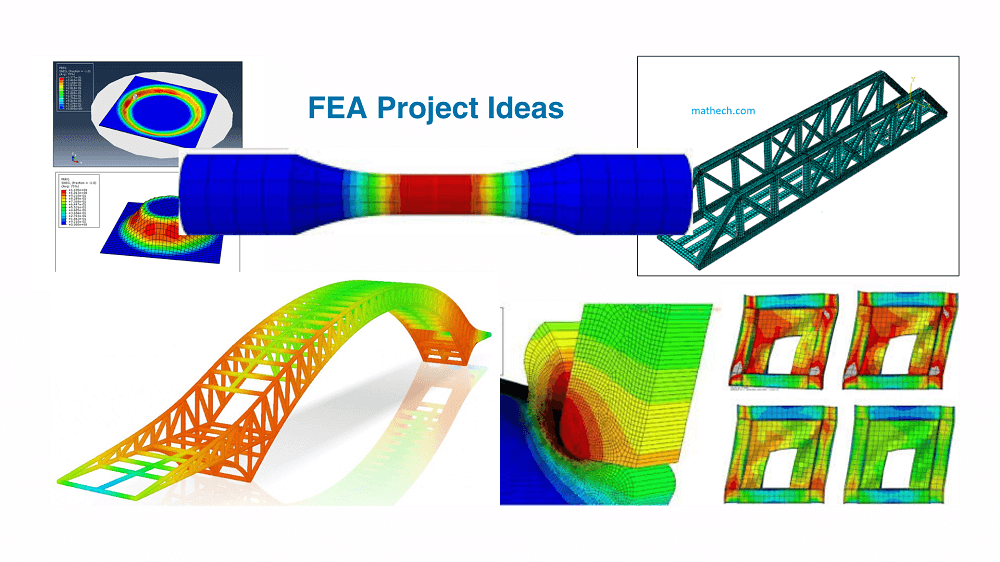

Here are 20 Finite Element Analysis (FEA) project ideas, each explained in a paragraph, categorized by difficulty level (Elementary, Intermediate, Advanced), and sorted from Elementary to Advanced.

🟢 FEA Elementary Level Projects

- Cantilever Beam Under concentrated Load

Analyze a cantilever beam fixed at one end and subjected to a point load at the free end. This classic FEA problem helps students to understand stress distribution, deformation, and how mesh refinement affects accuracy. Ideal for comparing analytical and numerical results in 2D or 3D.

- Simply Supported Beam Under Uniform Load

Simulation of a simply supported beam subjected to a uniformly distributed load using 2D plane stress or 1D beam elements. Students can visualize bending stress, deflection profiles, and validate against textbook formulas. This problem teaches how boundary conditions affect results.

- Plate with a Circular Hole Under Tension

Simulate a flat rectangular plate with a central hole under uniaxial tension. This project introduces stress concentration effects and how geometry impacts local stresses and it’s Ideal for understanding mesh refinement near discontinuities.

- Thermal Expansion of a Metal Bar

Apply a uniform temperature increase to a metallic bar and observe thermal expansion. This project introduces thermal-mechanical coupling, material thermal properties, and constraint-induced thermal stresses.

You can read about Step By Ste Abaqus Heat Transfer Tutorial

- Buckling of a Slender Column

Analyze a pinned-pinned column under axial compression to determine its critical buckling load. Use linear buckling analysis and compare with Euler’s formula. This project teaches stability analysis and eigenvalue extraction in FEA.

Here is an example of column buckling simulation using Abaqus

Click Here to Find Out More FEA Projects

🟡 Intermediate Level Projects by FEA Method

- Truss Bridge Under Distributed Load

Model a 2D truss bridge structure subjected to distributed loads (like vehicle weight). Analyze member forces, reaction forces, and deflections. This project emphasizes structural mechanics, constraint application, and multiple element connectivity.

in this picture you can see a steel bridge model simulated in Abaqus

- Heat Conduction in a Composite Wall

Simulate steady-state heat transfer through a multi-layered composite wall. Assign different thermal conductivities to each layer and observe temperature gradients. This introduces thermal boundary conditions, interfaces, and material property assignment.

Read more: Step by Step Analysis of a Composite Sheet in Abaqus

- Bimetallic Strip Bending simulation in FEA method

Model the bending of a bimetallic strip when heated. Each metal has different coefficients of thermal expansion. This project is great for coupled thermal-structural analysis and introduces complex thermal stress interactions.

- Contact Stress Between Two Cylinders

Simulate Hertzian contact between two cylinders under load. The project introduces contact definitions, surface interactions, and stress concentrations. Useful for understanding nonlinearity in FEA.

For more information check this post to learn How to Set Up Contact Interaction in Abaqus

- Modal Analysis of a Steel Plate

Conduct a modal analysis of a thin steel plate with fixed edges to determine its natural frequencies and mode shapes. This is useful for students interested in vibration analysis and structural dynamics.

- Perforated Sheet Under Shear Load

Model a thin sheet with regularly spaced holes subjected to in-plane shear. This project helps students to understand stress risers, material reduction effects, and how periodic patterns affect global stiffness.

- Bracket Mount Under Load

Simulate a 3D mechanical bracket with multiple holes and loading surfaces. Apply bolt forces or constraints and observe stress paths. This real-world simulation covers boundary condition complexities and design evaluation.

🔴 Advanced Level Projects for Finite Element Model Simulation

- Crash Simulation of an Automotive Bumper

Perform an explicit dynamic simulation of a car bumper impacting a rigid wall. Study impact forces, energy absorption, and plastic deformation. This project introduces nonlinear material behavior and dynamic contact modeling.

- Fatigue Life Prediction of a Shaft

Model a rotating shaft with fillets and keyways subjected to cyclic bending loads. Use stress-life (S-N) curves or strain-life (ε-N) approach to predict fatigue life. Teaches damage accumulation and fatigue modeling in FEA.

- Large Deformation of Rubber Seal (Hyperelasticity)

Analyze the deformation of a rubber O-ring under compression using a hyperelastic material model (e.g., Neo-Hookean, Mooney-Rivlin). This project involves nonlinear materials and large-strain kinematics.

- Thermal-Structural Coupled Analysis of a Disc Brake

Simulate a disc brake subjected to frictional heat during braking in Abaqus. Evaluate temperature rise and resulting thermal stresses. Introduces coupled fields (thermal and structural) with transient loading.

Check: Disc Brake Thermal-Stress Analysis in Abaqus

- Composite Laminate Under Bending

Model a multi-layer composite laminate beam subjected to bending. Each layer has different orientations and material properties. Requires orthotropic material models and knowledge of laminate theory.

- Fluid-Structure Interaction of a Pipe

Perform a coupled fluid-structure interaction (FSI) simulation where fluid pressure inside a flexible pipe causes deformation. This project combines CFD and FEM techniques and is suitable for Abaqus + CFD coupling (e.g., with Ansys Fluent or STAR-CCM+).

- Crack Propagation Using XFEM

Model a plate with a crack using Extended Finite Element Method (XFEM) and simulate its propagation under load. Introduces fracture mechanics, crack tip singularities, and cohesive zone modeling.

Read: Step-by-Step Crack propagation Analysis in a plate Using Abaqus

- Simulation a composite wing panel in Abaqus

Wing panels are critical parts of an aircraft’s wing, designed to withstand aerodynamic forces, fuel loads, and inertial loads while maintaining aerodynamic efficiency. Here’s a detailed breakdown of what a composite wing panel structural model is.