Is your Abaqus simulation stopping before it finishes? You’re likely facing a convergence problem that is one of the most common issues in finite element analysis (FEA). A convergence problem occurs when the Abaqus solver cannot find a stable solution, causing the analysis to stop unexpectedly. These interruptions can be frustrating, especially when they happen repeatedly, wasting both time and effort.

Understanding convergence in Abaqus is essential for running reliable simulations. A converged model means the internal forces are in balance with the applied loads, allowing the analysis to proceed smoothly. When this balance breaks down, the solver cannot continue, and the simulation stops. This guide explains why convergence fails and how you can fix it to achieve stable and accurate results.

In this guide, we’ll walk you through the main causes of convergence failure in Abaqus. The most common issues include contact problems, material behavior errors, large deformations, and poor mesh quality. For each of these, we provide clear and practical solutions. You’ll also find best practices to help you prevent convergence issues before they occur.

Follow our expert guidance to get your Abaqus simulations running smoothly again. With the right approach, you can eliminate convergence problems and achieve accurate, reliable results every time. Let’s walk through the proven methods that help you fix these issues and build more stable, efficient models.

1. What is Convergence and Why Does it Fail?

🔍 What Convergence Means in Abaqus

- Convergence happens when internal and external forces are in balance.

- The solver checks this balance at every increment.

- Residual forces are the unbalanced parts the solver tries to minimize.

- When residuals become small enough, the model has converged.

✅ Result: The simulation runs smoothly and produces stable, accurate results.

⚠️ Why Convergence Fails in Abaqus

- The solver can’t balance internal and external forces.

- Residual forces remain too large, stopping the analysis.

🔹 Common Causes

- Contact Problems: Sudden contact changes create large force jumps.

- Material Issues: Unrealistic plasticity or softening leads to instability.

- Large Deformations: Changing stiffness disrupts force balance or causes buckling.

- Poor Mesh Quality: Distorted or inverted elements give false stresses and break the solution.

✅ Result: Understanding these causes helps you identify and fix convergence failures early.

2. Identifying a Convergence Problem: Key Warning Signs

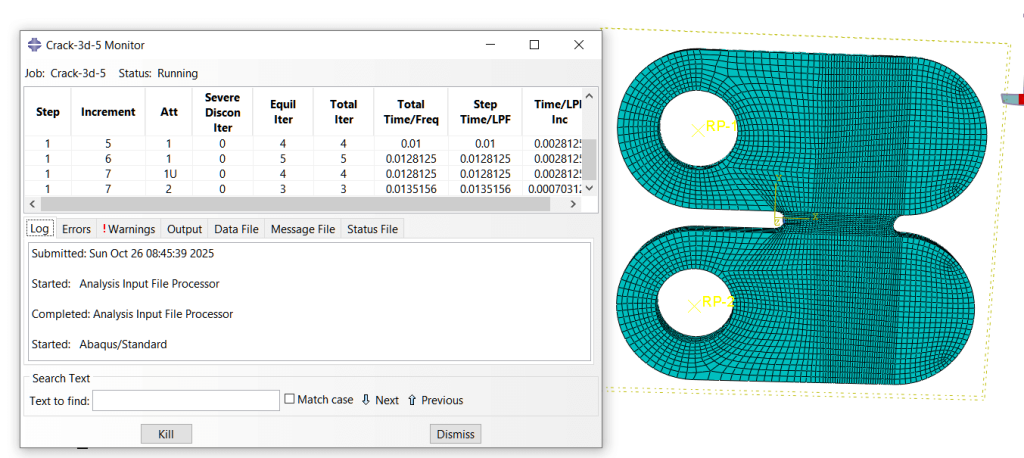

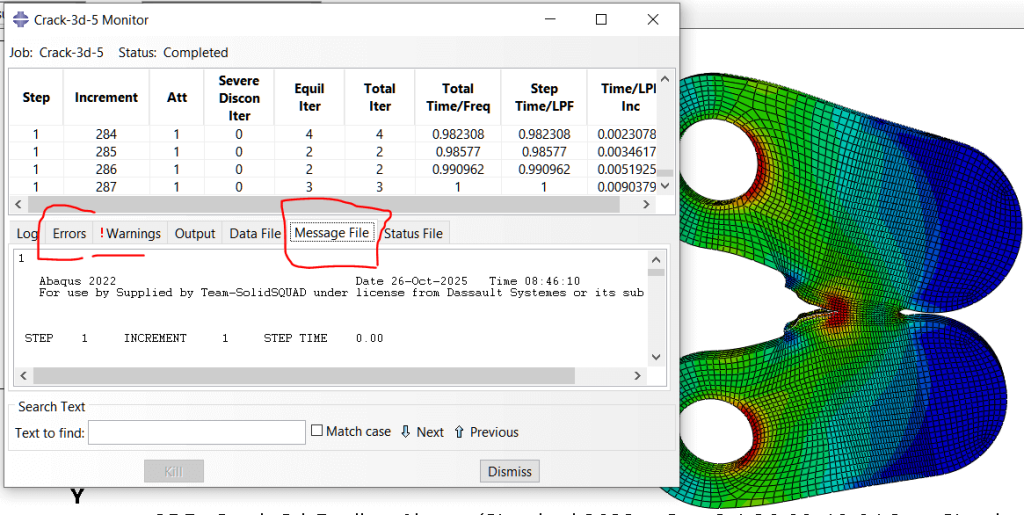

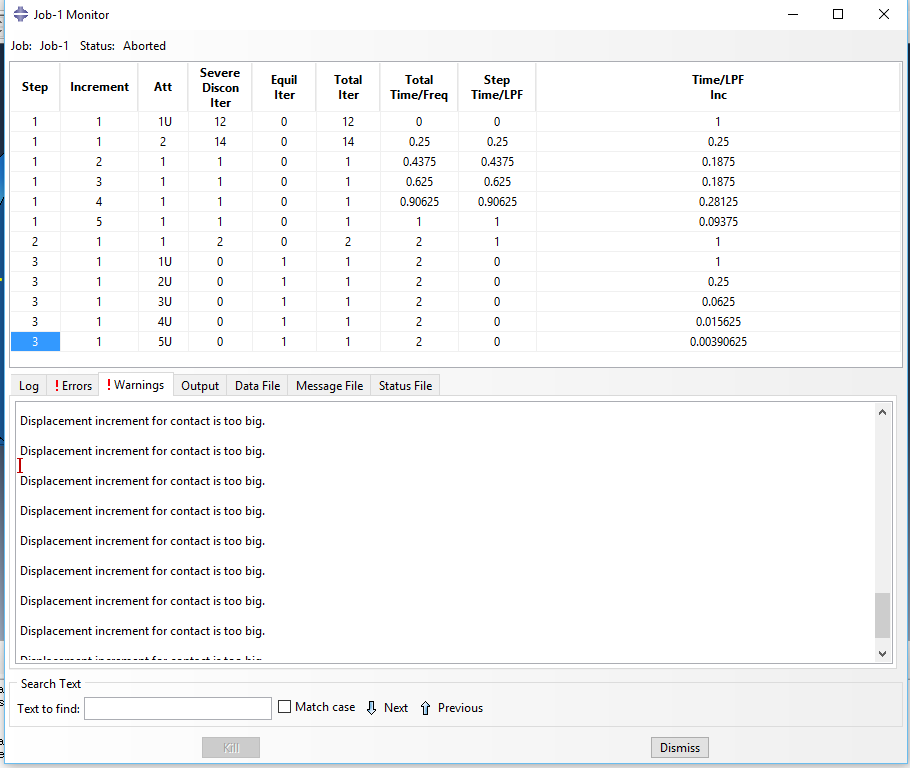

Your Abaqus job will stop prematurely. The Job Manager shows “Aborted” status. This is the first clear sign. The error file provides more details. Check the message file (.msg) carefully. Look for specific error phrases.

“Too many attempts” appears often. This means the solver tried repeatedly. It could not find equilibrium. “Severe discontinuity” is another common message. This indicates violent contact changes. Forces changed too suddenly.

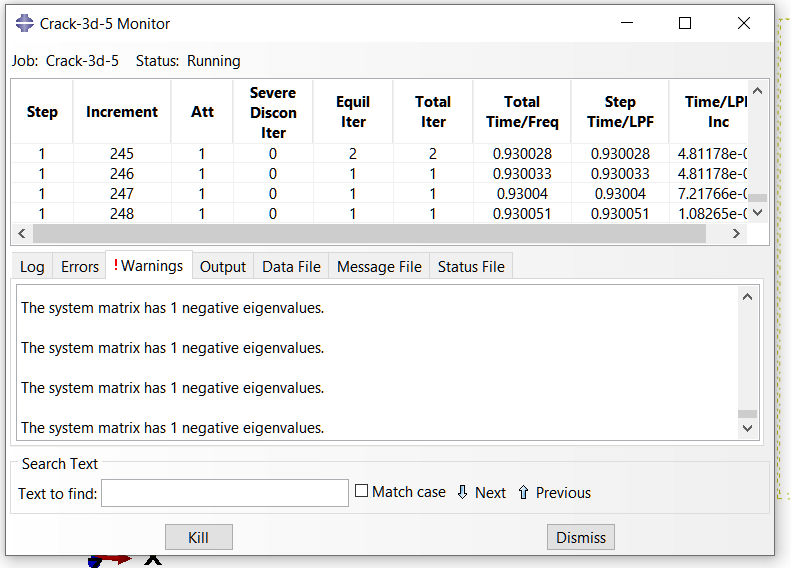

“Negative eigenvalue” warnings suggest instability. This often means buckling occurred. It can also indicate over-constraint. The time increment becomes very small. It may hit the minimum limit. The analysis cannot move forward.

Monitor the job diagnostics while running. Watch the increment number. If it keeps cutting back, trouble is coming. The solution progress stalls completely. These signs help you act fast. You can stop and investigate early.

3. The 10 Major Causes of Convergence Failures

3.1. Non-convergence in a static step (Newton-Raphson)

Typical message (example):**ERROR** THE ANALYSIS HAS NOT CONVERGED - INCREMENT ... FAILED TO CONVERGE

Causes: too large increment, severe nonlinearity, poor load ramp, bad element formulation, unstable contact.

Fixes:

- Reduce initial/time incrementation (Step → Edit → Initial increment / Minimum increment).

- Turn on line search (in GUI: Step → Edit → Solver controls → enable Line search).

- Use

NLGEOM=YESonly when needed (keyword:*STEP, NLGEOM=YES). - Improve mesh or element type (use second-order elements where appropriate).

- Add automatic stabilization: Step → Stabilization (damping factor 1e-4 → increase only if needed).

- If contact: relax contact settings (use penalty with small friction or adjust contact stiffness).

- If all above is done and still no solution, then use:

- *CONTACT CONTROLS, AUTOMATIC TOLERANCES

3.2. Contact non-convergence

Typical messages (examples):WARNING: CONTACT ITERATION DID NOT CONVERGE**ERROR** CONTACT COUPLING FAILED

Causes: poor contact initialization, too-stiff penalty, severe penetration, incompatible surfaces, inappropriate contact algorithm.

Fixes:

- Use Augmented Lagrange or change contact formulation (Surface to surface vs node-to-surface).

- Reduce contact stiffness (Contact → Interaction → edit contact property → reduce stiffness factor).

- Use contact separation/clearance/offset to avoid initial penetration.

- Refine mesh near the contact interface.

- Try small sliding vs finite sliding depending on problem.

- Enable automatic stabilization for contact if oscillatory.

3.3. Element distortion / badly shaped elements

Typical message:WARNING: ELEMENT 12586 HAS BECOME BADLY DISTORTED

Causes: large deformation in single layer of elements, inappropriate element formulation for large strains.

Fixes:

- Refine mesh and improve element aspect ratio.

- Switch to elements better for large deformation (e.g., C3D8R → C3D8I or C3D8R with hourglass control).

- Use remeshing / adaptive meshing (Abaqus/Explicit has ALE or adaptive remesh options).

- Reduce load increment size; use explicit dynamic if implicit cannot handle mesh distortion.

3.4. Material model instability / poor constitutive parameters

Typical message:**WARNING** NON-PHYSICAL MATERIAL RESPONSE DETECTED

(Or solver reports negative stiffness, etc.)

Causes: unrealistic input parameters, abrupt transitions, missing hardening, incorrect units.

Fixes:

- Check units (N, mm vs N, m).

- Smooth the material curve (use small strain vs large strain models appropriately).

- Add viscosity or rate dependence to stabilize (visco-plastic or small viscous regularization).

- For damage models, ensure proper regularization or mesh sensitivity control (use element size / material characteristic length).

- Read more about it : How to deal with excessive element distortion in Abaqus?

3.5. Convergence failure caused by insufficiently small time increments

Typical message:**ERROR** STEP PROGRESS FAILED TO CONVERGE; TIME INCREMENT REDUCED TO MINIMUM

Causes: time increment reduced to minimum but still no convergence.

Fixes:

- Reduce tolerances carefully (change displacement/tolerance thresholds in Step → Solver Controls).

- Increase nonlinear iteration limit (Iterations per increment).

- Use automatic stabilization or replace implicit with explicit if dynamic effects matter.

- Revisit boundary conditions and apply load more gradually (use amplitude curves).

3.6. Rigid body motion / missing boundary conditions

Typical message:**ERROR** RIGID BODY MOTION DETECTED

or many zero pivot messages during matrix factorization.

Causes: model not constrained properly, parts free to translate/rotate.

Fixes:

- Add necessary constraints or reference points.

- Use encastre or pinned BCs for test runs to check model stability.

- For assemblies, use tie constraints correctly, check connector definitions.

3.7. Solver linear algebra issues (singular matrix / zero pivot)

Typical message:**FATAL ERROR** ZERO PIVOT ENCOUNTERED

or **ERROR** MATRIX IS SINGULAR

Causes: disconnected DOFs, duplicate nodes, zero-stiffness elements, bad constraints.

Fixes:

- Run model check: Mesh → Verify mesh connectivity, duplicate nodes removal.

- Check for elements with zero Young’s modulus or zero cross-section area.

- Ensure loads/BCs are not applied to free nodes only.

- Use a small stiffness tie to connect floating parts.

3.8. Explicit solver instability (too large time step / mass scaling side effects)

Typical message:**WARNING** MASS SCALING USED

or energy balance shows KINETIC ENERGY >> INTERNAL ENERGY (sign of instability)

Causes: overly aggressive mass scaling or too-large time step causing non-physical dynamics.

Fixes:

- Reduce mass scaling.

- Refine mesh to reduce critical time increment.

- Use smaller explicit step time or switch to implicit if quasi-static.

- Monitor kinetic vs internal energy to ensure stable dynamic response.

3.9. Convergence issues with nonlinear contact + plasticity

Typical message:**WARNING** LARGE PLASTIC STRAIN CAUSING NONCONVERGENCE

or contact iteration failures while plastic deformation occurs.

Causes: combined geometrical non-linearity and material non-linearity magnify numerical difficulties.

Fixes:

- Ramp load slower (use amplitude curve).

- Use smaller increments and enable line search.

- Use stabilized implicit with viscous regularization on plasticity if available.

- Increase mesh density in plastic zones and use reduced integration cautiously.

3.10. Problems from constraint equations / multi-point constraints (MPC)

Typical message:**ERROR** INCONSISTENT CONSTRAINT EQUATIONS

or solver prints warnings about singularities in constraint matrix.

Causes: conflicting MPCs, overconstrained nodes, incompatible kinematic definitions.

Fixes:

- Check constraint definitions for conflicts (duplicate multipoint constraints).

- Replace MPC with tie or kinematic coupling where appropriate.

- Use rigid body reference nodes instead of many MPCs to simplify constraints.

- Visualize constraint equations to find overlapping constraints.

4. Quick practical checklist to debug any convergence problem

- Run a linear static check first. If linear works, nonlinearity causes failure.

- Simplify the model. Remove contact, use elastic material, run a small case.

- Check units, BCs, and connections. Most problems come from missing constraints or wrong units.

- Refine locally. Mesh refinement near high gradients often fixes issues.

- Use logs. Read

jobname.datandjobname.msgfor iteration details and element warnings. - Try different solver controls. Line search, reduced tolerances, more iterations.

- If contact repeatedly fails, try surface smoothing, different contact formulations, or small gaps.

- If nothing helps, try an explicit quasi-static run (apply load slowly) to get a reference solution.

4.1. Notes on exact messages

Abaqus prints many variants. I used typical/representative message text above (examples you will see in .dat, .msg, or on screen). Exact phrasing can vary by version and whether it’s Abaqus/Standard or Abaqus/Explicit. Always check jobname.dat and jobname.log for the precise error lines and the iteration history — those files show the final reason (e.g., which increment failed, element/step numbers, contact pair names).

This guide will show you how to build and mesh a 3D model in Abaqus

5. Preventing convergence problems before happening

It means building your Abaqus simulations correctly from the start. It focuses on preventing convergence problems before they happen. Instead of fixing errors later, you create stable models initially. You use smart strategies that help the solver work efficiently. This includes proper mesh design and good material definitions.

You also set up steps and contacts carefully. These practices make your analysis more reliable. They reduce the risk of failure during solving. This leads to accurate results on the first attempt.

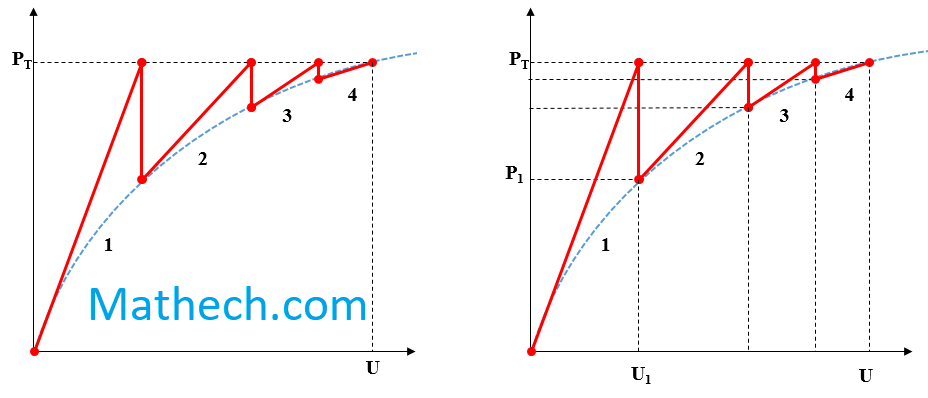

5.1. Increasing increments Strategy: Giving the Solver a Chance

Do not use default increments. They are often too large. Set a small initial increment size. Start with 0.01 or smaller. This helps the solver begin gently. Allow for many increments. Set the maximum to 1000 or more. This gives the solver enough attempts. Also set a small minimum increment. Use 1E-5 or similar. This prevents early termination. Good incrementation guides the solver successfully.

5.2. Stabilization: A Careful Helping Hand

Stabilization helps with tricky models and adds small damping forces. These forces guide the solution. Use automatic stabilization in Abaqus. Set a small dissipation factor. Try 1E-7 initially. Check the energy dissipation later. Ensure it stays below 1-2% of internal energy. Too much stabilization affects results. Remove it once the model works properly.

6. Conclusion: Achieving Reliable Simulation Results

Mastering convergence is essential for successful engineering simulation. By understanding the root causes of failure and implementing systematic solutions, you transform frustrating errors into valuable learning experiences. Consistent results come from applying proven best practices throughout your modeling process. Remember that patience and methodical troubleshooting always outperform random guessing. Each solved convergence problem strengthens your FEA expertise and builds confidence in your results. The skills you develop ensure your simulations provide accurate, trustworthy data for engineering decisions. Continue applying these principles to achieve reliable outcomes project after project.