This guide explains every Abaqus element type used in FEM simulation – solid, shell, beam, truss, membrane, and continuum elements. You’ll learn how element shapes, integration rules, and degrees of freedom affect accuracy, convergence, and computation time. Updated for 2025, it includes selection tips for structural, thermal, and coupled analyses, helping you choose the most efficient element for your model.

Introduction: Why Element Choice is Critical in FEA

Selecting the right element type in Abaqus is the foundation of any successful Finite Element Analysis. The correct choice ensures accuracy, efficiency, and reliable results. A poor choice leads to errors, slow solutions, or physically meaningless answers. This guide provides a comprehensive overview of Abaqus element families to help you make informed decisions for your simulations.

1. Understanding Abaqus Element Naming Conventions

Abaqus uses a structured naming system for elements that encodes their key properties such as; shape, dimensionality, number of nodes, formulation, and behavior type.

Each element name (like C3D8R or S4R) follows a consistent logic. Once you understand the code, you can identify an element’s features instantly.

1.1. Most Basic Formats

Most Abaqus elements follow this pattern:

[Family][Dimensionality][Nodes][Modifier]A name like S4R breaks down as:

- S: Family (Shell)

- 4: Number of nodes

- R: Technique or formulation (Reduced integration)

For example: C3D8R

| Code Part | Meaning |

|---|---|

| C | Continuum (solid element family) |

| 3D | 3-dimensional |

| 8 | 8 nodes per element |

| R | Reduced integration formulation |

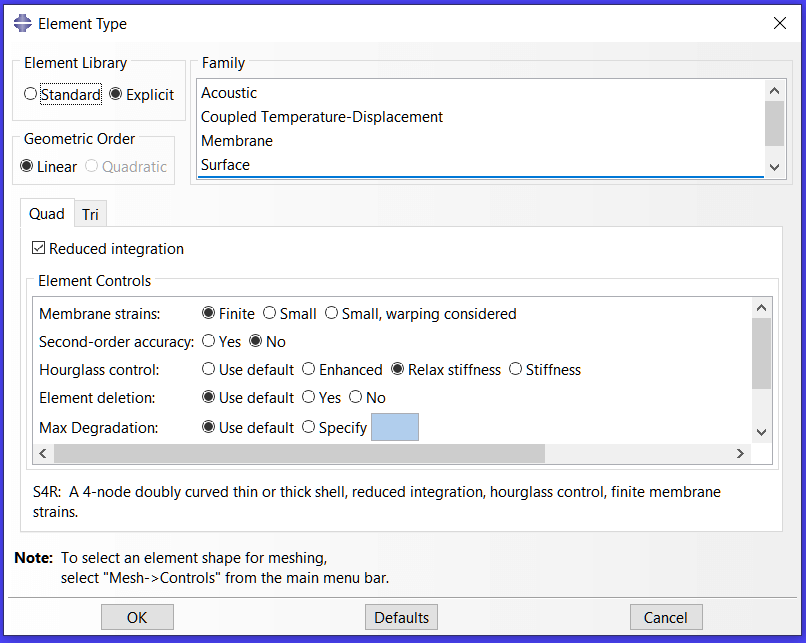

C3D8R ElementThis simple system applies across most element types, including solid, shell, beam, truss, membrane, and cohesive elements.

1.2. Common Element Families in Abaqus

| Prefix | Family Type | Description |

|---|---|---|

| C | 3D Continuum | 3D solid elements for stress and thermal analysis |

| S | Shell | 2D elements for thin or thick structures |

| M | Membrane | 2D tension-dominated elements |

| B | Beam | 1D structural elements for bending and axial behavior |

| T | Truss | 1D axial-only elements |

| COH | Cohesive | Used for interface and delamination modeling |

| DC | Diffusion/Heat transfer | Used in thermal or mass diffusion problems |

1.3. Integration and Formulation Codes

| Code | Description |

|---|---|

| R | Reduced integration (faster, less accurate for bending if distorted) |

| I | Incompatible mode (adds flexibility for bending) |

| H | Hybrid formulation (used for nearly incompressible materials) |

| P | Pore pressure (coupled fluid–structure analysis) |

| AX | Axisymmetric (2D model revolved about an axis) |

1.4. Example Interpretations

| Element | Description |

|---|---|

| C3D8 | 3D solid, 8-node brick, full integration |

| C3D8R | 3D solid, 8-node brick, reduced integration |

| S4R | 4-node shell, reduced integration |

| B31 | 2-node beam element with cubic interpolation |

| CAX4H | 4-node axisymmetric hybrid element |

1.5. Choosing the Right Element

- Use reduced integration (R) for speed, but check for hourglassing.

- Use hybrid (H) elements for rubber or incompressible materials.

- Use incompatible mode (I) for bending-dominated problems.

- Always test element performance through mesh convergence studies.

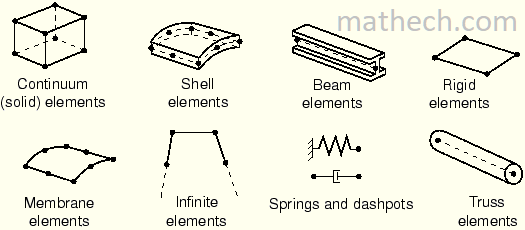

2. Continuum (Solid) Elements: For 3D Bulk Structures

Continuous elements – also known as solid elements – are the basis of most 3D simulations in Abaqus. They represent materials with significant thickness in all directions and capture the full 3D stress and strain states. These elements are used in the simulation of mechanical parts, assemblies, and assemblies where deformation occurs throughout the volume, not just the surface.

2.1. Purpose and Application

Continuum elements model 3D bulk behavior in structures such as:

- Machine components

- Connectors and brackets

- Pressure vessels

- Cast or forged parts

- Components under compression, torsion, or complex load paths

They are ideal when stresses vary significantly through the thickness or in multiple directions.

2.2. Common Continuum Element Families

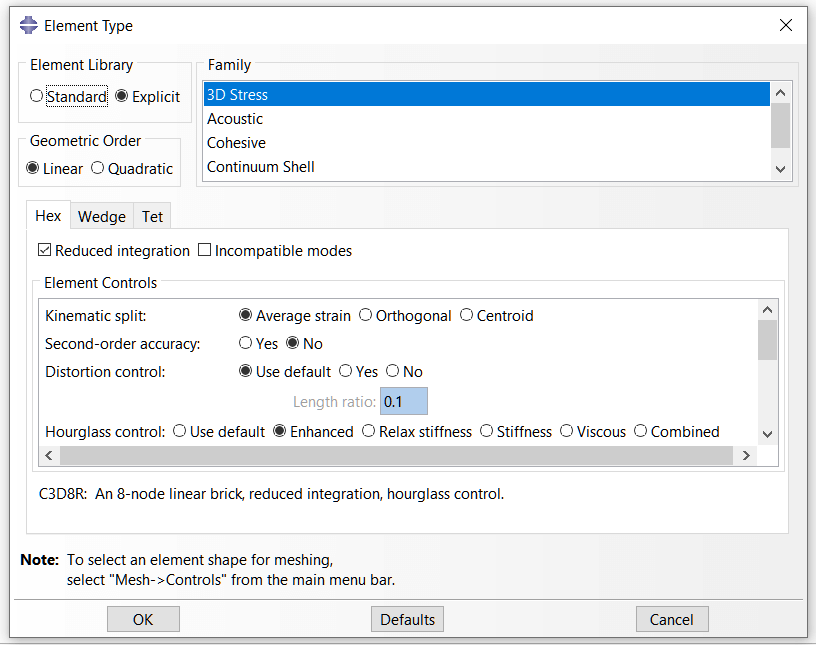

| Element | Description | Nodes | Key Features |

|---|---|---|---|

| C3D8 | 3D brick (hexahedral) element | 8 | Full integration, accurate but slower |

| C3D8R | 3D brick, reduced integration | 8 | Faster; may require hourglass control |

| C3D10 | 3D tetrahedral element | 10 | Quadratic; handles complex geometry |

| C3D20R | 3D brick, quadratic reduced integration | 20 | High accuracy for nonlinear analyses |

| C3D4 | 3D tetrahedral, linear | 4 | Simple but less accurate under bending |

2.3. Integration and Formulation Options

Reduced Integration (R): Improves computational speed but can cause hourglassing in poorly shaped elements.

Hybrid Formulation (H): Used for nearly incompressible materials like rubber or plastic under large deformation.

Incompatible Mode (I): Enhances bending performance in first-order elements (e.g., C3D8I).

2.4. Key Modeling Guidelines

✅ Use Hex Elements When Possible

Hexahedral (brick) elements like C3D8 or C3D20R give better accuracy and stability than tetrahedral ones for the same mesh density.

✅ Avoid Distorted Elements

Poorly shaped elements cause convergence problems and unrealistic stress peaks. Maintain aspect ratios close to 1:1 when possible.

✅ Run Mesh Convergence Studies

Always test element density and type to ensure results are not mesh-dependent.

Learn how to build and mesh a 3D model in Abaqus.

✅ Check Deformation Gradients

In large-deformation problems, verify that elements do not invert or distort excessively.

2.5. When to Use Continuum Elements

Use continuum elements when:

- The structure has significant thickness or 3D stress distribution.

- The load causes complex internal stress fields.

- You need to capture volumetric deformation, such as compression, torsion, or hydrostatic pressure.

Avoid them for thin plates or shells those are better modeled with shell or membrane elements.

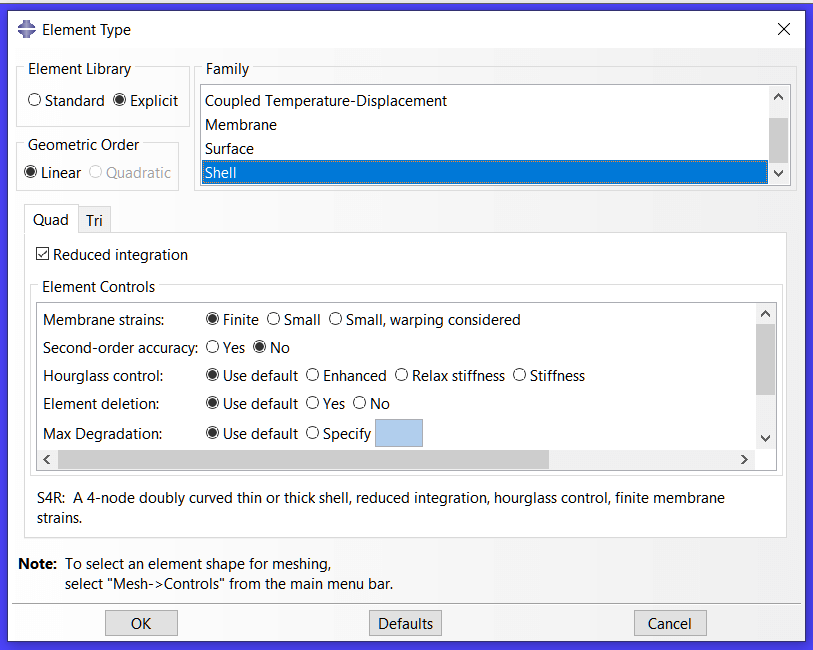

3. Shell Elements: For Thin-Walled Structures

At Mathech Consulting Team, we use shell elements in Abaqus when analyzing thin-walled components where one dimension (thickness) is much smaller than the other two. Shell elements efficiently capture both in-plane and bending behaviors without the high computational cost of full 3D solid models.

They are ideal for plates, sheet-metal parts, pressure vessels, enclosures, and structural panels components where stresses vary primarily across the surface rather than through the volume.

3.1. Why Use Shell Elements?

Shell elements model membrane (in-plane) and bending (out-of-plane) responses together.

They are computationally lighter than 3D continuum elements and maintain excellent accuracy for structures with small thickness.

We select shell elements when:

- The thickness-to-length ratio is below 1:10.

- The stress state is dominantly surface-based.

- We need to analyze buckling, vibration, or large deformation in thin parts.

3.2. Common Shell Element Types in Abaqus

| Element | Nodes | Type | Key Features |

|---|---|---|---|

| S4 | 4 | Linear quadrilateral | Full integration, general use |

| S4R | 4 | Linear quadrilateral | Reduced integration, faster, widely used |

| S8R | 8 | Quadratic quadrilateral | High accuracy, smoother curvature |

| S3 | 3 | Linear triangular | For irregular geometries or transitions |

| S3R | 3 | Linear triangular reduced | Efficient for complex or curved meshes |

Among these, we often recommend S4R because it balances accuracy and efficiency for most engineering cases.

3.3. Integration and Formulation Notes

Reduced Integration (R): Lowers CPU time but can cause hourglassing if mesh quality is poor.

Finite-Membrane Strain Option: Used for large-deformation problems such as forming or bending.

Thickness Definition: Each shell element has a defined thickness, either constant or varying by node.

Offset Option: We can offset the shell’s reference surface from the mid-plane to represent real geometry more accurately.

3.4. Modeling Guidelines from Mathech Experience

✅ Mesh Quality Is Critical

Use a uniform, regular mesh. Distorted elements reduce accuracy in bending zones.

✅ Define Correct Thickness

Assign realistic thickness values in the Section Manager. Incorrect values directly affect stiffness and stress results.

✅ Use Quadratic Elements for Curved Surfaces

Elements like S8R handle curvature better and produce smoother stress gradients.

✅ Check Edge Constraints

Shell edges often connect to beams, solids, or other shells. Always verify continuity and compatible boundary conditions.

✅ Prefer Shells Over Solids for Thin Structures

They reduce computation time drastically without losing essential accuracy.

3.5. When to Use Shell Elements

Use shell elements in:

- Sheet metal parts

- Thin-walled pressure vessels or tanks

- Aerospace or automotive body panels

- Structural plates, roofs, or enclosures

- Composite laminates (using layered shell sections)

Avoid them when the part has significant 3D stress gradients through the thickness. in those cases, use continuum (solid) elements instead.

4. Beam Elements in Abaqus: Modeling Slender Frameworks Efficiently

At Mathech Consulting Team, we use beam elements in Abaqus to simulate slender structures where one dimension (length) is much greater than the other two (cross-section dimensions).

Beam elements efficiently represent bending, torsion, shear, and axial forces with minimal computational cost that makes them ideal for structural frames, trusses, supports, and mechanical linkages.

4.1. Purpose and Application of Beam Elements

Beam elements model the centerline of slender members instead of their full volume.

They are extremely efficient for structures dominated by bending and axial loads, such as:

- Structural frames and bridges

- Support beams or reinforcements

- Shafts and pipelines

- Robotic arms or linkages

- Truss and lattice assemblies

We often use beams when full 3D solid modeling would add unnecessary complexity or computation time.

4.2. Common Beam Element Types in Abaqus

| Element | Nodes | Type | Key Features |

|---|---|---|---|

| B31 | 2 | Linear beam | Most commonly used; cubic interpolation of displacement |

| B32 | 3 | Quadratic beam | Higher accuracy for curved geometry |

| B33 | 3 | 3D quadratic beam | Used for advanced 3D frame systems |

| PIPE31 | 2 | Pipe element | Specialized for circular cross-sections |

| FRAME3D | 2 | Legacy element | Used in simple structural analysis |

4.3. Cross-Section Definition for Beam Elements

Each beam element requires a defined cross-section that represents its shape and stiffness.

Abaqus provides various section types, including:

- Rectangular, Circular, I-section, T-section, and Pipe

- Composite sections for multi-material beams

- User-defined profiles using the Profile Manager

The section properties directly control the bending stiffness, torsional rigidity, and mass distribution of the element.

Read more about beam element here: The wide range of elements that are available in ABAQUS

4.4. Modeling Guidelines for Beam Elements from Mathech Experience

✅ Align the Local Axes Properly

The local coordinate system defines bending directions. Misalignment can cause unrealistic rotations or twisting.

✅ Use Beam Orientations Consistently

Always define the orientation vector for each beam to avoid torsional instability.

✅ Connect Beams Correctly

Ensure nodes at intersections are shared or connected with coupling constraints to transfer forces accurately.

✅ Mesh Density

Use a finer mesh at load application points or joints to capture local bending behavior.

✅ Verify Cross-Section Properties

Incorrect dimensions lead to wrong stiffness or mass calculations.

4.5. When to Use Beam Elements

Use beam elements when:

- The structure is slender and behaves mainly through bending or axial loads.

- The cross-section remains constant or varies slowly along the length.

- The interest is in global structural response, not local stress details.

Avoid beams when the structure has thick or complex 3D geometry, local contact, or nonlinear deformation . in such cases, use solid or shell elements instead.

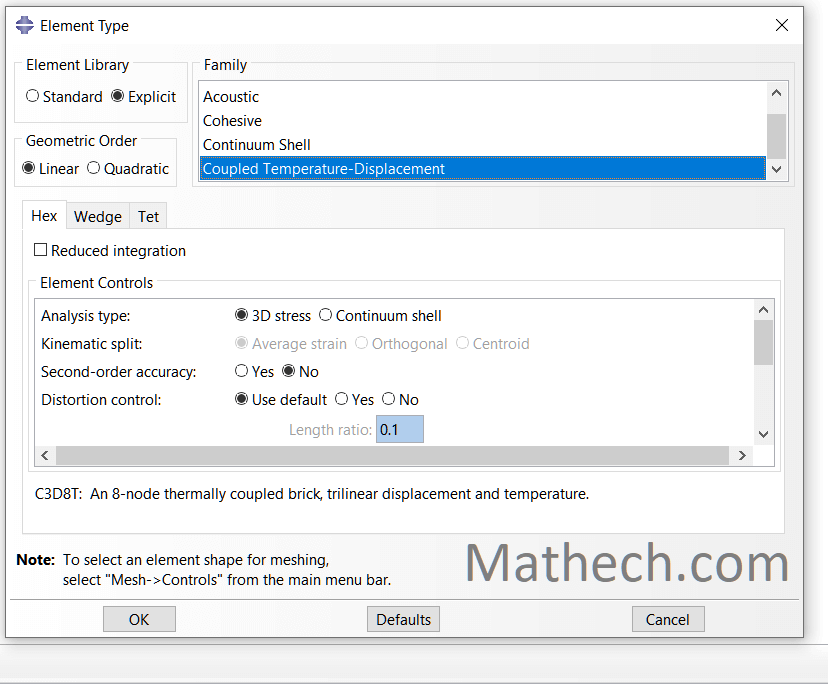

5. Coupled Temperature–Displacement Elements

At Mathech Consulting Team, we use Coupled Temperature–Displacement elements in Abaqus to simulate problems where thermal and mechanical fields interact.

These elements allow us to analyze how temperature changes affect stresses and deformation, and how mechanical work generates heat that is a crucial capability in thermo-mechanical analysis.

They are essential for accurate modeling in welding, metal forming, electronics, and high-temperature structural applications.

5.1. Purpose and Physical Meaning

Coupled temperature–displacement elements solve both temperature (thermal) and displacement (mechanical) degrees of freedom simultaneously.

This means Abaqus calculates:

- Temperature distribution (°C or K)

- Resulting thermal expansion or contraction

- Heat generation from plastic work or friction

- Stress and strain caused by temperature gradients

In essence, these elements connect the thermal field and structural deformation field inside a single analysis step.

5.2. Typical Applications

We use coupled temperature–displacement elements in analyses such as:

- Welding and heat treatment simulations

- Thermal fatigue and stress relaxation

- Electronic component heating (e.g., chip packages, solder joints)

- Frictional heating in contact problems

- Composite curing and polymer processing

- Brake systems and turbine components under cyclic heating

In all these cases, temperature changes directly influence stress and strain evolution.

5.3. Common Element Types of Coupled Temperature–Displacement in Abaqus

| Element | Description | Dimensionality | Key Features |

|---|---|---|---|

| C3D8T | 8-node brick | 3D | Linear, full integration, thermomechanical |

| C3D8RT | 8-node brick | 3D | Reduced integration, faster, good for nonlinear analyses |

| C3D20RT | 20-node brick | 3D | Quadratic, high accuracy for complex geometries |

| CAX4T | 4-node axisymmetric | 2D | For rotationally symmetric heat–structure models |

| CPE4T | 4-node plane strain | 2D | Used in plane-strain thermomechanical analyses |

The “T” suffix in the element name indicates temperature–displacement coupling.

5.4. Key Modeling Features

✅ Direct Thermomechanical Coupling

Both fields are solved together, allowing heat generation and thermal expansion to influence each other.

✅ Transient or Steady-State Capability

Supports time-dependent heating, cooling, and mechanical loading.

✅ Material Coupling

Thermal and mechanical material properties can vary with temperature. for example, temperature-dependent elastic modulus, thermal conductivity, or expansion coefficient.

✅ Internal Heat Generation

You can include heat from plastic deformation, viscous dissipation, or frictional contact.

✅ Boundary and Contact Conditions

Supports thermal contact conductance, film conditions, and radiation.

5.5. Mathech Modeling Guidelines

At Mathech Consulting Team, we follow strict modeling practices to ensure stable and realistic results:

- Use compatible meshes for thermal and mechanical domains.

- Apply accurate thermal boundary conditions (convection, radiation, or contact conductance).

- Always define temperature-dependent material properties for realistic response.

- Use reduced-integration elements (R) for large or nonlinear models to improve performance.

- Avoid excessive element distortion; it causes numerical instability during coupled iterations.

5.6. When to Use Coupled Temperature–Displacement Elements

Use these elements when:

- The temperature field significantly influences mechanical deformation.

- You need to capture thermal stresses or heat generation from mechanical work.

- Sequential thermal–mechanical analysis is not sufficient.

For faster solutions.void them for purely mechanical or purely thermal problems that use dedicated structural or heat transfer elements instead.

6. Common Element Selection Mistakes and How to Avoid Them

At Mathech Consulting Team, we often help clients fix simulation errors that come from using the wrong Abaqus element type.

Element selection directly controls the accuracy, stability, and speed of your analysis.

Even well-built models can fail if the elements don’t match the physics of the problem.

Here are the most frequent mistakes that we see and how you can avoid them.

6.1. Using Solid Elements for Thin Structures

The mistake:

Many engineers model thin plates or shells using 3D solid elements (C3D8 or C3D20).

This dramatically increases element count and often leads to locking or poor bending accuracy.

How to avoid it:

- For thin or moderately thick parts, use shell elements (S4R, S8R).

- Maintain at least 4–6 elements through the thickness if solids are necessary.

- Compare solid vs. shell results to confirm equivalence.

Mathech Tip:

If the thickness-to-length ratio is below 1:10, shell elements are usually more efficient and accurate.

6.2. Using Tetrahedral Elements for Simple Geometry

The mistake:

Tetrahedral elements (C3D4, C3D10) are easy to mesh but often less accurate and more prone to distortion than hexahedral (brick) elements.

Overusing them leads to stiff results and poor stress prediction.

How to avoid it:

- Use hex elements (C3D8R, C3D20R) whenever geometry allows.

- If tetrahedrals are necessary, use quadratic tets (C3D10) instead of linear ones.

- Check element distortion and refine near stress gradients.

Mathech Tip:

In our consulting work, we replace tets with hexes in critical areas to improve accuracy by up to 30% without increasing runtime.

6.3. Mixing Incompatible Element Types

The mistake:

Combining elements with different formulations or dimensionalities (for example, solids with shells or beams) without proper coupling creates stress discontinuities and unstable contact.

How to avoid it:

- Use tie constraints or surface coupling between dissimilar element types.

- Align nodes or surfaces for consistent load transfer.

- Avoid connecting beam directly to solid elements without interface constraints.

Mathech Tip:

We always verify force continuity across interfaces by checking reaction force balance in post-processing.

6.4. Ignoring Reduced Integration and Hourglassing

The mistake:

Using reduced integration (R) elements improves speed but may introduce hourglassing and a false zero-energy deformation mode that distorts results.

How to avoid it:

- Use hourglass control or enhanced hourglass stiffness in Abaqus.

- For bending-dominated problems, switch to full integration or incompatible mode (I) elements.

- Visually inspect element deformation modes to detect non-physical motion.

Mathech Tip:

We often use C3D8I instead of C3D8R for bending or contact-heavy problems and it keeps speed but improves accuracy.

6.5. Using Linear Elements in Curved or Contact Regions

The mistake:

Linear elements (4-node shells, 8-node solids) can’t capture curvature or contact pressure distribution accurately.

This leads to uneven stresses and artificial stiffness.

How to avoid it:

- Use quadratic elements (S8R, C3D20R) for curved or contact interfaces.

- Refine mesh gradually near contact zones.

- Avoid sharp element transitions between linear and quadratic meshes.

Mathech Tip:

Quadratic elements handle curvature naturally and we use them for pressure vessels, fillets, and curved shells.

6.6. Neglecting Temperature–Displacement Coupling in Thermal Problems

The mistake:

Engineers often run separate thermal and mechanical analyses even when strong coupling exists — leading to inaccurate thermal stresses.

How to avoid it:

- Use coupled temperature–displacement elements (C3D8T, C3D20RT) for heat-induced deformation.

- Apply realistic temperature-dependent material properties.

- Use transient analysis for heating and cooling cycles.

Mathech Tip:

We use coupled elements for welding, brake heating, and turbine blade cooling simulations where temperature affects mechanical response directly.

6.7. Over-Refining the Mesh Without Justification

The mistake:

Overly dense meshes increase CPU time without improving accuracy.

It often causes numerical noise or solver instability.

How to avoid it:

- Run mesh convergence studies — refine only where gradients are high.

- Use local mesh controls instead of global refinement.

- Compare reaction forces and energy errors, not just visual smoothness.

Mathech Tip:

We aim for a balance: a mesh fine enough for accuracy but coarse enough for efficient iteration.

7. Conclusion: Building a Reliable Modeling Foundation

At Mathech Consulting Team, we believe that element selection is the foundation of every reliable Abaqus model.

The accuracy, stability, and computational efficiency of your simulation all depend on how well the chosen element type reflects the true physics of your problem.

A well-structured model begins with understanding how each element family behaves — solids for 3D stress fields, shells for thin-walled components, beams for slender structures, and membranes or cohesive elements for specialized interfaces.

Each choice carries assumptions about geometry, deformation, and load transfer. Ignoring these assumptions often leads to misleading results, even when convergence appears successful.

Frequently Asked Questions (FAQ) – Element Types in Abaqus

Abaqus provides several element families including solid (continuum), shell, beam, truss, membrane, and coupled temperature–displacement elements. Each family is designed for specific geometry types and deformation behaviors. Selecting the correct one ensures accuracy and convergence in simulations.

Choose solid elements for 3D parts with significant thickness, shell elements for thin-walled structures, and beam elements for slender members. The decision depends on geometry, stress distribution, and computational efficiency. At Mathech, we help clients identify the best option for each project.

Incorrect element selection can cause unrealistic stiffness, locking, or convergence failure. For example, using solid elements for thin parts can lead to shear locking. Matching the element type to the real physical behavior of the structure prevents such issues and ensures accurate results.

These elements are used in thermomechanical simulations where heat transfer affects deformation or stress. Abaqus simultaneously solves temperature and displacement fields, making these elements essential for processes like welding, thermal expansion, or heat treatment analysis.

Review geometry thickness, aspect ratios, and loading type before assigning elements. Use reduced integration when possible, avoid excessive mesh distortion, and verify results through convergence testing. Consulting experts like the Mathech team ensures your model setup is physically and numerically sound.

Need Help Selecting the Right Element for Your Model?

Choosing the wrong element can derail your project. The FEA experts at Mathech can review your model and recommend the most efficient and accurate element types for your specific application, saving you time and ensuring reliability.

Completely I share your opinion. In it something is also to me it seems it is excellent idea. I agree with you.

——