This guide will show you how to build and mesh a 3D model in Abaqus. We break it down into simple, clear steps. You’ll learn the entire process from start to finish. Follow us to create reliable simulations.

Why a Good Mesh is the Foundation of Accurate FEA

A good mesh is the most important part of FEA. It divides your model into small pieces called elements. These elements help Abaqus calculate stresses and strains. A poor mesh will lead to incorrect answers and errors. This tutorial will ensure that you create a reliable mesh.

Step 1: Defining the Geometry – Native Creation vs. Import

Every simulation starts with geometry. First, you need to import your 3D model into Abaqus. You can create it directly in the software. Or you can import it from a CAD program. This step sets up all the subsequent steps.

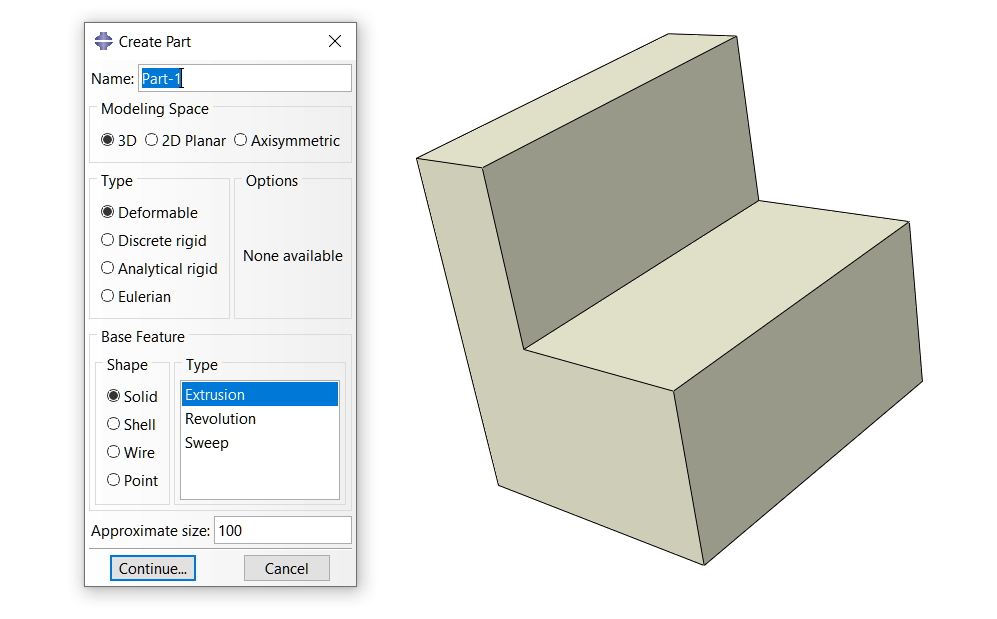

1. Creating a Simple 3D Part in Abaqus/CAE

You can create simple parts within Abaqus. Use the Part module to create basic shapes. This module is great for blocks, cylinders, and plates. It’s a quick way to start a new model without any other software.

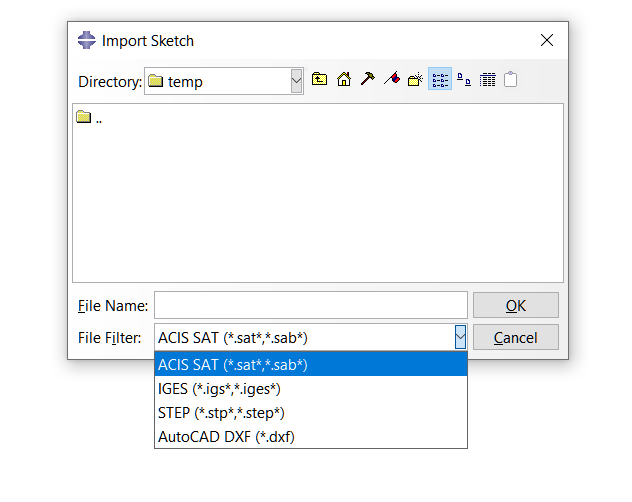

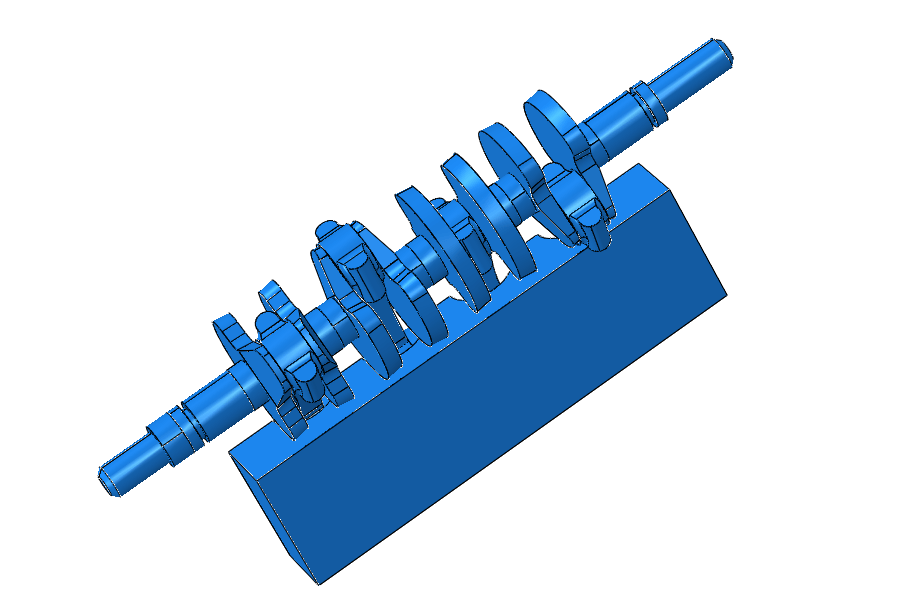

2. Importing Complex Geometry from CAD Software

Most real-world designs are made in CAD software. You can import these models into Abaqus. Common file types are STEP and IGES. This lets you work with complex, detailed geometry from the start.

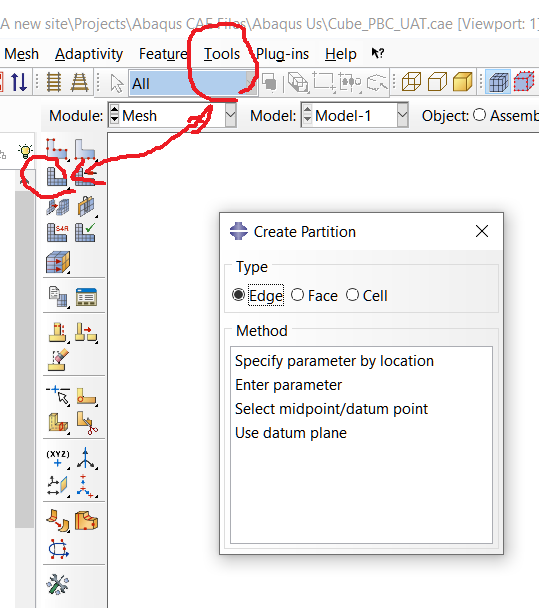

Step 2: Cut Your Model with Partitions

Partitioning is like cutting a complex shape into simpler pieces. This is a key step to a good mesh. These smaller, more regular shapes are easier for Abaqus to mesh correctly. This is the secret to a clean, neat mesh.

1.Why You Need to Partition

You need partitions to control your mesh. A complex shape often leads to a messy, poor-quality mesh. Partitions create straight edges and simple volumes. This allows for a structured mesh, which is more accurate and reliable.

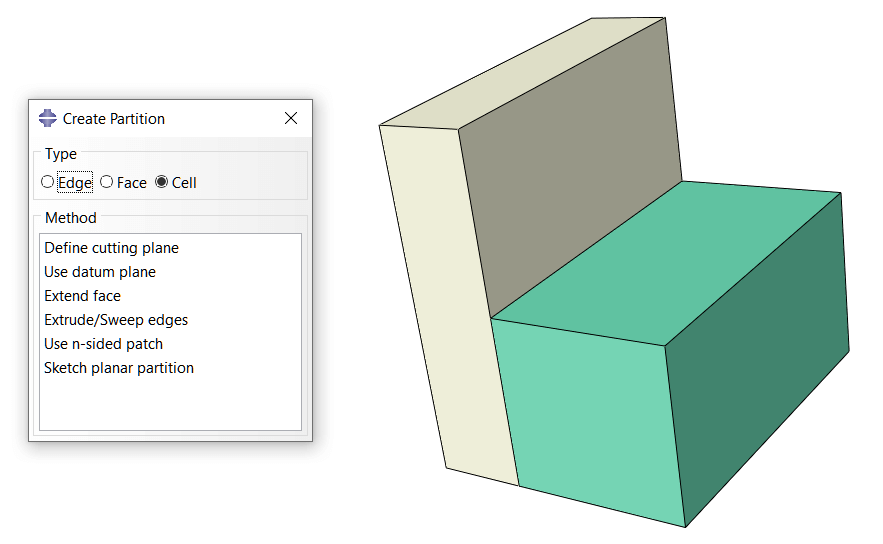

2. How to Partition a Model

You can split your model using tools in the Part module. Use the “Define Cutting Plane” tool. You can also sketch a line to partition with. This breaks your model into smaller, more manageable sections for meshing.

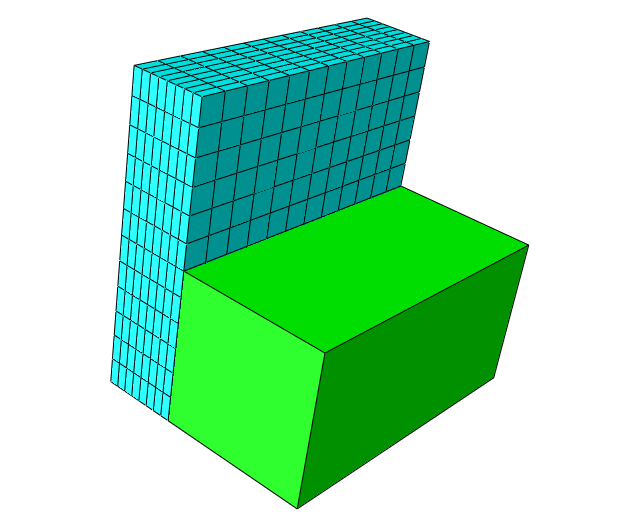

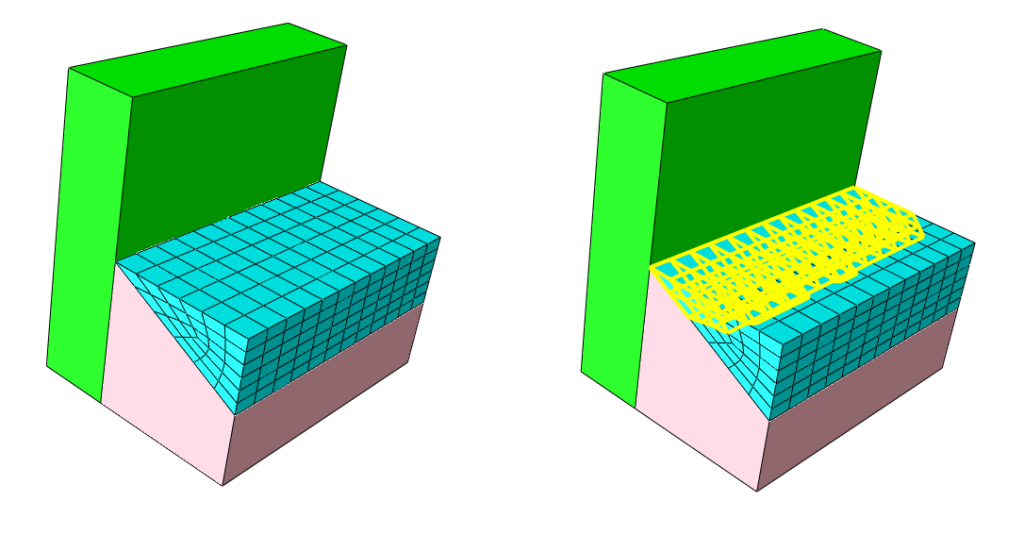

Example: Cutting a fragment

The fragment shown in the previous section has been divided into two parts. Here we can easily mesh one part of it. One of the benefits of partitioning is that we can use a finer mesh in the parts that are more sensitive, given the physics of the problem.

Check here for more examples of Abaqus projects

Step 3: Assigning Mesh Controls and Element Types

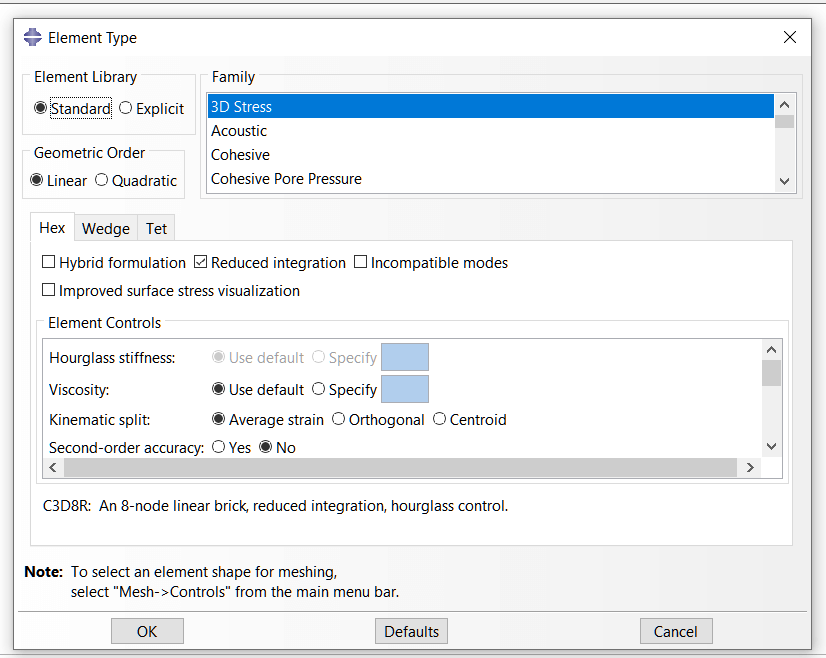

Now you need to tell Abaqus how to mesh. This involves choosing the appropriate element type and controls. These settings will determine the behavior and accuracy of your mesh. Getting it right here will prevent many common problems later on.

1. Choosing the Right Element Type for Your 3D Model

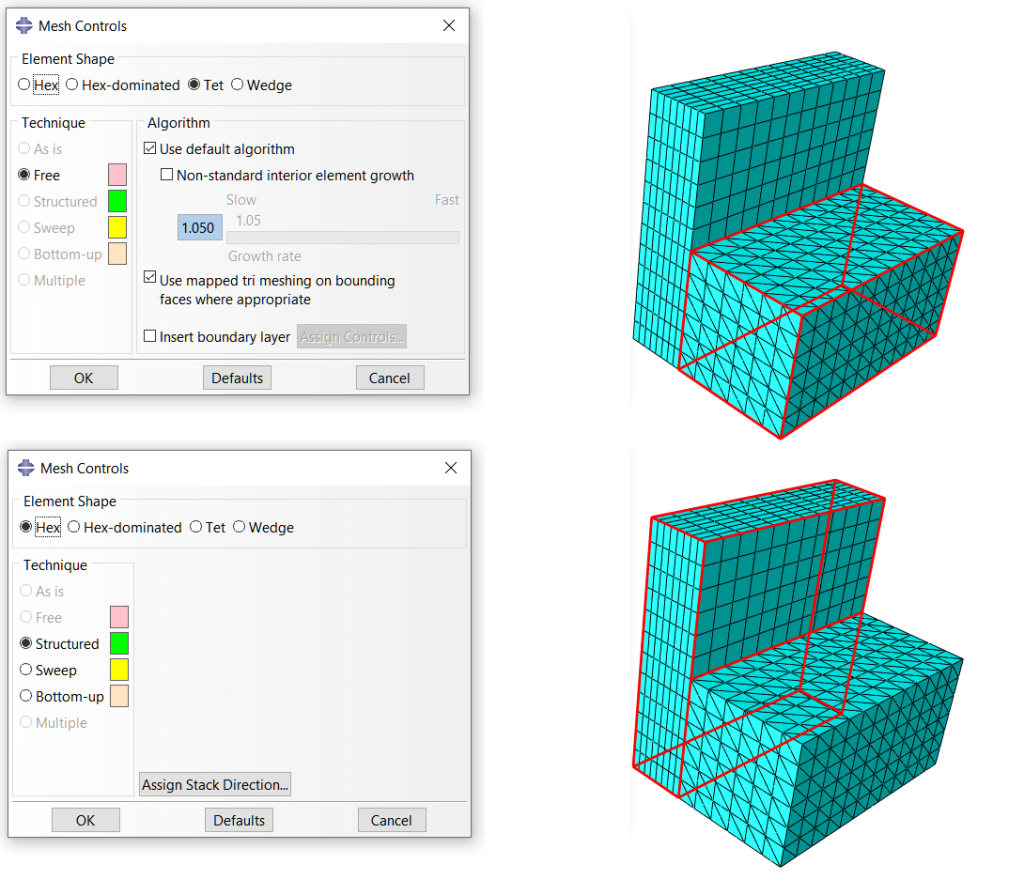

You must choose between hexagonal and tetrahedral elements. Hexagonal elements are often more accurate and efficient. Tetrahedral elements are better for very complex shapes. Your choice depends on the geometry of the model and your accuracy needs.

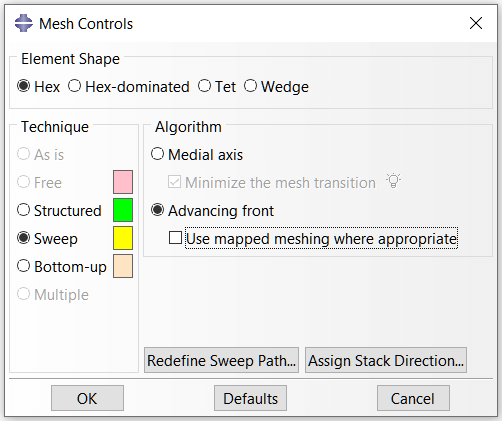

2. Configuring Mesh Controls: Structured, Swept, and Free

Mesh controls guide Abaqus in how to fill a part. You can select the “Sweep” option for a clean hexagonal mesh. The “Structured” option also provides a regular pattern. The “Free” option is used for complex areas where a 3D mesh is acceptable.

Step 4: Seeding and Generating the Mesh in Abaqus

This is where you generate the mesh. First, you set the element size using seeding. Then you tell Abaqus to generate the mesh. Finally, you need to check that it was generated without any errors.

1. Global and Local Seeding: Controlling Mesh Density

Seeding controls how fine or coarse your mesh is. A global seed sets the overall size. You can add local seeds to critical areas. A finer seed in high-stress zones gives you more accurate results there.

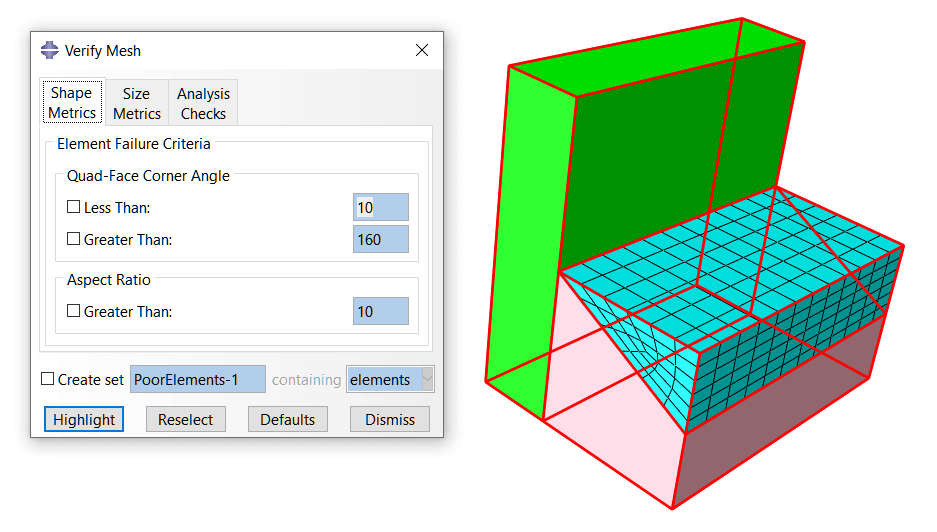

2. Generating the Mesh and Checking for Errors

Click the “Mesh Part” button to create the mesh. Then, use the “Verify Mesh” tool. Look for any red marks that indicate failed elements. A good mesh is complete and has no error warnings.

Step 5: Verifying Mesh Quality: The Mathech Expert Checklist

Creating a mesh is not the final step. You must check its quality. Abaqus has tools to analyze the mesh. You need to look at specific metrics to ensure the mesh is good for simulation.

1. Important Quality Checks

Check the aspect ratio and Jacobian of your elements. The aspect ratio should be close to 1.0. A high Jacobian means an element is too distorted. These numbers tell you if your mesh is healthy.

Aspect Ratio

Think of the aspect ratio as a measure of an element’s shape. It compares the element’s longest side to its shortest side.

Good Aspect Ratio (Close to 1.0): The element looks like a perfect square or cube. This is ideal. It gives Abaqus a well-shaped area to calculate accurately.

Bad Aspect Ratio (Much higher than 1.0): The element is long and skinny, like a pencil or a pancake. These distorted shapes can cause inaccurate results. They make it hard for Abaqus to calculate stresses correctly.

Jacobian

The Jacobian measures how much an element is distorted when it is mapped from a perfect shape.

Good Jacobian (Close to 1.0): The element is not distorted. Its corners are well-defined.

Bad Jacobian (Much less than 1.0 or negative): The element is twisted or warped. A highly distorted or “inverted” element (negative Jacobian) will cause your analysis to fail. Abaqus cannot calculate properly with a broken element.

2. How a Bad Mesh Gives Bad Results

A bad mesh produces incorrect stress values. It can show stress concentrations that are not real. It also causes the analysis to stop with errors. A quality mesh is the only path to trustworthy results.

Fix Common Mesh Problems in Abaqus

Sometimes, your first mesh will have issues. Do not worry. Most mesh problems can be fixed. Here are solutions for the most frequent errors users face.

1. Meshing Tricky Shapes

Some organic shapes are very hard to mesh. If partitions do not work, switch to tetrahedral elements. Use a fine global seed. The “Free” mesh control often works best for these complex geometries.

2. Fixing a Bad Mesh

If you have twisted elements, go back a step. Try a different partitioning strategy. Use a finer local seed in the problem area. Sometimes, changing the element type is the fastest solution.

Conclusion

You now know how to create and mesh a 3D model in Abaqus. Start with geometry, then partition, then set controls. Always check your mesh quality. These steps will lead to successful and accurate FEA simulations in Abaqus.

This made meshing my turbine blade model much easier. The tip about virtual topology for small features was a game-changer. Thank you!

We use this as training material for new hires. The mesh quality metrics section is particularly useful. A part 2 on troubleshooting poor-quality elements would be valuable

Perfect for my graduate research! The explanation of element types was great. Is there a rule of thumb for when to use tetrahedral vs. hexahedral elements for accuracy?

This guide saved me so much time. The section on partitioning to control the mesh was exactly what I needed for a complex injection mold. Any tips for hex-dominant meshing on organic shapes?

Very clear steps! I used this for a bracket analysis. Could you do a follow-up on setting local mesh seeds and mesh convergence studies?

Finally, a guide that explains mesh controls clearly. The visuals on swept meshing helped a lot. How do you decide between medial axis and advancing front for a sweep?