Setting up units correctly in Abaqus is the first step to a successful simulation. Abaqus has no built-in unit system. This means that you are responsible for choosing and maintaining consistent units throughout your model. One unit mistake can lead to completely wrong results. Your model may work perfectly, but the stresses, forces, and displacements may be completely incorrect.

This guide shows you how to avoid these critical errors. In this article we have provided practical examples to explain how to use units in Abaqus. We will explain the basic concept of consistent unit systems. You will learn the most common and reliable systems used in engineering analysis. We provide a clear, step-by-step method for setting up your model units. Our best practices will help you manage units from start to finish. Follow this tutorial to ensure that your Abaqus results are always physically correct and reliable.

Introduction to Units in Abaqus

Understanding units is essential in Abaqus. The software does not recognize units such as pounds or meters. Instead, it only processes numerical values. You need to make sure that these numbers represent a consistent unit system. This means that all of your inputs must match. Your material properties, loads, and dimensions must work together. A consistent system produces physically meaningful results. This is your first and most important modeling responsibility.

1. Why Abaqus Has No Default Unit System

Abaqus is designed for global use. Engineers around the world use different measurement systems. Some use SI units and others use US units. The software remains neutral to serve all users. It processes numbers without assuming their units. This flexibility allows for the creation of any fixed system. You can work in meters or millimeters. The choice is yours to build and manage. This design makes the software universally applicable.

2. Importance of Consistent Units in FEM Simulations

Unit consistency ensures that your results are correct. All input values must be from the same system. Your units of length, force, mass, and time must match. Incompatible units introduce dangerous errors. Your stresses can be a thousand times too high. Your displacements can be a million times too small. These errors can remain hidden until catastrophic failure. Compatible units protect your analysis from these errors. They ensure that your solutions reflect real-world physics.

Correctly setting and managing units in Abaqus is a fundamental prerequisite for any analysis procedure you choose, as even the most sophisticated solver will produce meaningless results without a consistent unit framework

Common Unit Systems Used in Abaqus

Most Abaqus users work with fixed unit systems. These systems ensure internal consistency across all inputs. The key is to maintain consistency between units. Popular systems include SI and US Customary units. Some engineers create modified versions for convenience. Understanding these systems helps prevent dangerous computational errors.

1. SI (Metric) Unit System

The SI system uses the meter, kilogram, and second. Length is usually in meters or millimeters. Mass is measured in kilograms. Time uses seconds for all calculations. Forces are entered in newtons. Stresses are automatically calculated in pascals. This system works well for international projects. It is widely used in academic and research settings.

SI system: meter (m), kilogram (kg), second (s), newton (N), pascal (Pa).

2. US Customary Unit System

This system uses inches, pounds, and seconds. Length is usually measured in inches. Force is entered in pounds (lbf). Mass uses the slug for dynamic analysis. Stresses are calculated in pounds per square inch (psi). This system is still common in American industry. It is often used in the automotive and aerospace fields. Choosing the Right System for Your Model.

US Inch system: inch (in), pound-mass (lbm), second (s), pound-force (lbf), psi.

Millimeter system: millimeter (mm), ton (ton = 1000 kg), second (s), newton (N), megapascal (MPa).

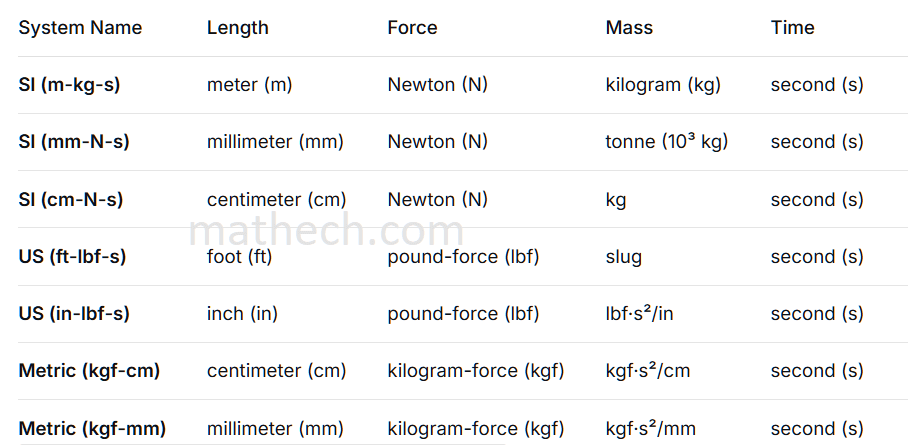

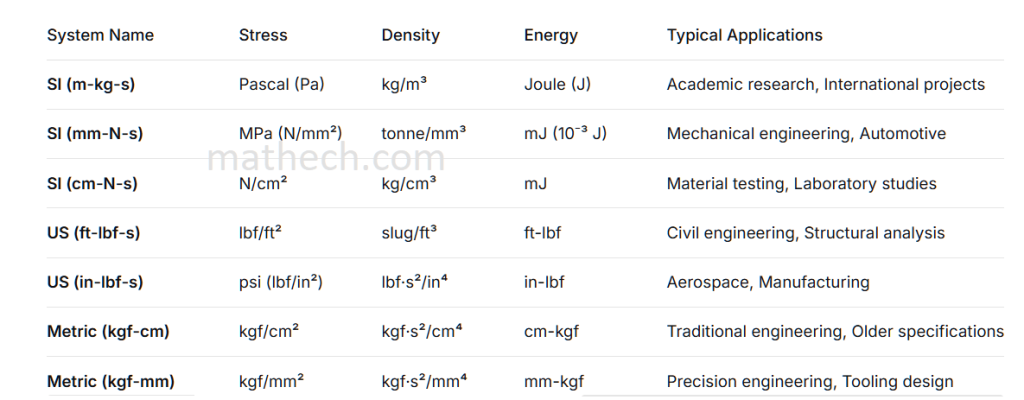

3. Extended Unit Systems for Abaqus Analysis

While most engineers use standard SI or US unit systems, Abaqus supports any consistent unit framework through proper dimensional analysis.

Extended systems include specialized combinations like SI(cm-N-s) for laboratory measurements or Metric(kgf-mm) for traditional engineering applications.

The fundamental principle remains unchanged: all physical quantities must maintain dimensional harmony across length, force, mass, and time.

For example, in a kgf-mm system, stress naturally computes in kgf/mm² when force and length units align accordingly.

The complete extended table demonstrates how to maintain coherence across seven different systems while highlighting their respective engineering applications.

Success with any system depends entirely on rigorous consistency rather than the specific units chosen.

How to Set Up Units in Abaqus Step by Step

Creating a consistent unit system requires careful attention at every stage of modeling. Start by choosing a consistent system and systematically applying it to all components. Document your chosen system to maintain clarity throughout your workflow. This systematic approach ensures that all physical quantities interact correctly during simulation.

Step 1: Define Units for Geometry

When creating or importing geometry, make sure that all dimensions are aligned with your chosen unit system. If you are working in millimeters, all part dimensions should be entered as millimeter values. For imported CAD files, verify that the scale factor matches your intended units. This essential step will prevent scaling errors that can make wrong the entire analysis.

Step 2: Define Units for Material Properties

Material parameters should match your geometric units. Young’s modulus for steel is approximately 200 GPa (200,000 MPa) when using millimeters. In inches, this becomes approximately 29×10^6 psi. Density values require special attention to maintain consistent mass units throughout your chosen system.

Step 3: Set Units for Loads, Boundary Conditions, and Output

Apply forces, stresses, and restraints using your designated unit framework. A force in Newtons with a millimeter geometry will produce stresses in MPa, while pounds with an inch will produce stresses in psi. Ensure that all input values and requested output values maintain this consistency for reliable results.

Step 4: Verify Unit Consistency Before Running an Analysis

Before running your Abaqus Job, systematically verify unit consistency across all aspects of the model. Create a simple hand calculation to verify the magnitude of the expected deformation. Check that stress concentrations appear in logical locations. This final validation step identifies unit mismatches that could invalidate your results.

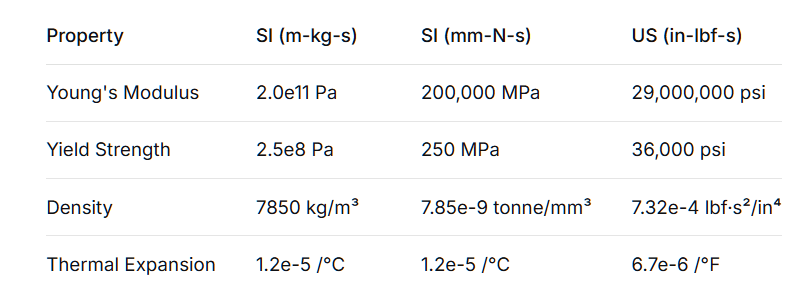

Material properties units conversion:

Converting material properties requires careful dimensional analysis, as values must align with your chosen length, force, and mass standards.

For example, a steel’s Young’s Modulus of 200 GPa equals 200,000 N/mm² (MPa) in an SI(mm) system, but becomes approximately 29 million psi when using US customary units with inches.

Density demands particular attention: 7850 kg/m³ converts to 7.85×10⁻⁹ tonne/mm³ for an SI(mm) model, or 0.000729 lb-s²/in⁴ for an inch-pound-second system.

Always use precise conversion factors and double-check derived units like density and pressure to ensure all terms remain consistent within your selected framework, thus maintaining physical accuracy across all calculations.

Material properties (such as Young’s modulus, density, and viscosity) must be set according to the selected unit system.

Several unit systems are popular in engineering:

- SI Units: Uses meters for length, kilograms for mass, and seconds for time.

- US Customary Units: Employs inches for length, pounds for force, and seconds for time, with mass in pounds-mass or slugs.

- mm-g-s System: Uses millimeters for length, grams for mass, and seconds for time, often with force in dynes or Newtons.

Practical examples of units in Abaqus

To demonstrate the practical application of unit consistency, we will walk through two common engineering scenarios. These examples will show how to implement a coherent unit system from start to finish, ensuring all inputs from geometry to results are physically accurate.

Detailed Examples of Each System

1. SI (m-kg-s) – Standard International System

- Length: 2.5 m (beam length)

- Force: 1000 N (applied load)

- Mass: 850 kg (structural mass)

- Stress: 2.1e8 Pa (210 MPa steel yield strength)

- Density: 7850 kg/m³ (steel density)

- Energy: 1500 J (impact energy)

2. SI (mm-N-s) – Modified SI for Engineering

- Length: 2500 mm (same beam length)

- Force: 1000 N (same applied load)

- Mass: 0.85 tonne (same mass)

- Stress: 210 MPa (same material strength)

- Density: 7.85e-9 tonne/mm³ (converted density)

- Energy: 1.5e6 mJ (same energy)

3. US (in-lbf-s) – American Engineering System

- Length: 98.43 in (same beam length)

- Force: 224.8 lbf (same load)

- Mass: 5.83 lbf·s²/in

- Stress: 30,450 psi (same material)

- Density: 7.32e-4 lbf·s²/in⁴

- Energy: 13,275 in-lbf

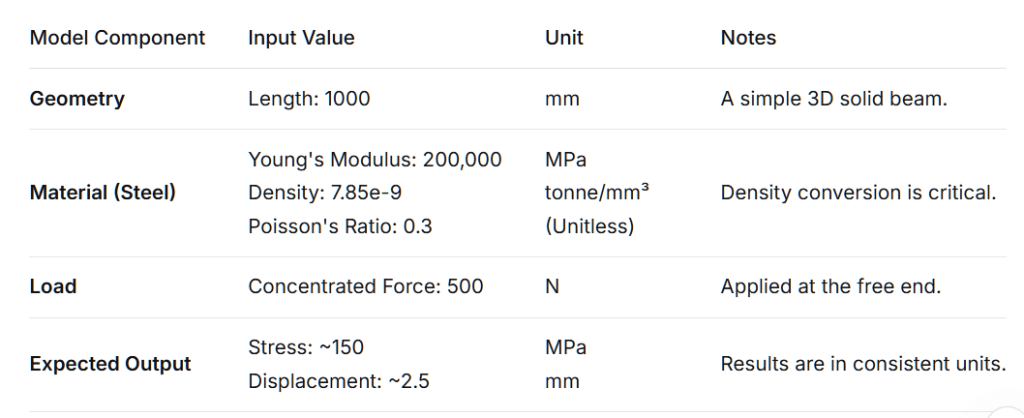

Example 1 – Steel Beam (SI Units)

For a steel cantilever beam, we use the SI(mm) system. We would model the beam with dimensions in millimeters (e.g., 1000 mm long). The material property for steel would be defined with a Young’s Modulus of 200,000 MPa (N/mm²) and a density of 7.85e-9 tonne/mm³. A concentrated load would be applied in Newtons (N), and the resulting stress would be automatically calculated in MPa. This ensures displacement and stress results are directly interpretable.

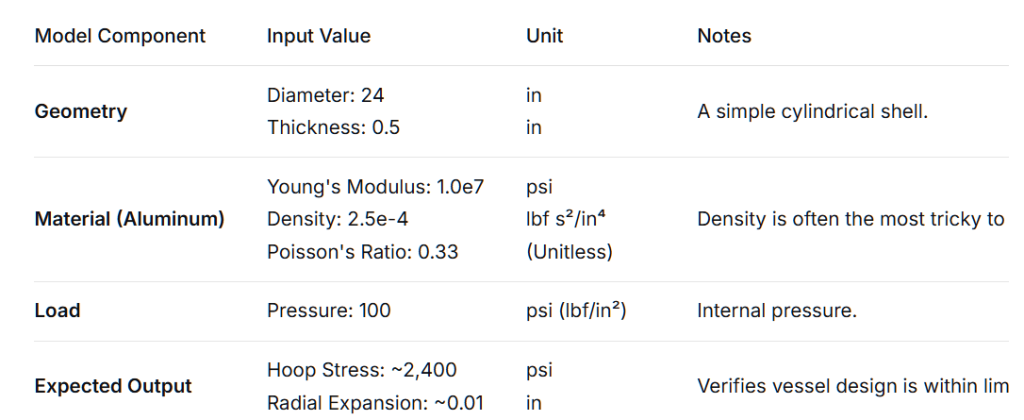

Example 2 – Pressure Vessel (US Units)

For an aluminum pressure vessel, we use the US Unit (inch) system. The vessel’s geometry, like its diameter and wall thickness, would be defined in inches. The aluminum’s Young’s Modulus would be set as approximately 1.0e7 psi, and its density as 2.5e-4 lb-s²/in⁴. The internal pressure would be applied in psi (lbf/in²). Using this consistent system, the output stress will also be in psi, providing a correct analysis of the vessel’s integrity.

Example 3 – Aluminum material properties in Abaqus

Here’s a concise table showing Aluminum material properties in different unit systems for the specified parameters:

Example 4 – Steel (ASTM A36)

See more Abaqus projects and units

Best Practices for Managing Units in Abaqus

Establishing reliable unit management practices prevents costly errors and ensures simulation accuracy. These systematic approaches help maintain consistency throughout your modeling workflow, from initial setup to final result verification.

Using Unit Checklists

Create and use a standard checklist for every project. This list should verify all model components use the same unit system. For example, confirm that geometry, material properties, and loads all align with your chosen framework like the SI(mm) system we demonstrated earlier. A checklist provides a crucial final review before running any analysis.

Keeping Consistent Documentation

Maintain clear documentation within your model and project files. Always note your chosen unit system in the model description. Use consistent naming conventions that include units for loads and material properties. This practice ensures all team members understand the framework, preventing the mixing of units between different contributors working on the same project.

Verifying Results Through Dimensional Analysis

Perform quick hand calculations to verify your simulation outputs make physical sense. For instance, if you applied a 500N load to a steel beam as in our previous example, compare the Abaqus stress results with basic beam theory calculations. This reality check helps catch unit inconsistencies that might otherwise go unnoticed despite the analysis completing successfully.

These practices form a comprehensive quality control system that safeguards your simulations against common unit-related errors, ensuring reliable and trustworthy results for your engineering decisions.

Frequently Asked Questions (FAQ) – Abaqus Units

Abaqus has no default unit system. The software only processes numerical values without assuming any units. You must define and maintain a consistent unit system throughout your entire model.

Use our unit verification checklist and perform hand calculations to verify results. Check that geometry, material properties, loads, and outputs all align with your chosen unit system. Compare expected vs. actual stress and displacement values.

No, never mix different unit systems in one model. Choose one consistent system (like SI-mm or US-inch) and use it for all inputs. Mixing units creates dangerous scaling errors that produce physically meaningless results.

Inconsistent units lead to completely wrong results that may appear plausible but are physically incorrect. Your stresses could be thousands of times too high/low, leading to dangerous design decisions and potential structural failures.

Convert results using standard conversion factors after analysis. For example, multiply MPa results by 145 to get psi, or multiply mm displacements by 0.03937 to get inches. Never mix units during the analysis phase.

Conclusion and Recommendations for Setting units in Abaqus

Finally, Abaqus has no built-in unit system. To get correct answers, you must choose a consistent set of units. We recommend using a standard system such as SI units. Always check that all your inputs use the same units. This includes material properties, loads, and geometry. Carefully checking the units will prevent errors and ensure that your results are meaningful.

Useful resources for studying units in Abaqus

- Units in Abaqus comprehensive guide for simulation – Technia Blog

- How do I get Abaqus to show units discussion on Reddit

- Abaqus Units detailed explanation and examples – CAE Assistant

- How to avoid errors with the units in Abaqus practical tips – TecnoDigital School

- Understanding Units in ABAQUS detailed analysis – Medium

- Abaqus units discussion in engineering forum – Eng-Tips