Laser welding joins metal parts together using a focused laser beam. This method is fast, precise, and common in modern manufacturing. Actual welding tests can be expensive and time-consuming. That’s why welding simulations are used to investigate the possible outcomes of different welding types.

With Abaqus laser welding simulation, engineers can visualize temperature fields, residual stresses, and distortions without performing costly experiments. This guide provides a step-by-step setup of a laser welding model in Abaqus, including heat source definition, boundary conditions, and result interpretation.

By the end, you’ll know how to perform a complete finite element analysis of laser welding that helps you to improve design accuracy, optimize process parameters, and reduce trial-and-error testing in real production.

Our team uses the most accurate method available to simulate the laser welding process in Abaqus. In this post, we describe in detail how to model critical phenomena such as temperature distribution, residual stress, and deformation of the part being welded.

Introduction to Laser Welding

Laser welding is a technique where a focused laser beam melts and joins materials, commonly metals or thermoplastics, with high precision. It’s widely used in industries like automotive and aerospace for its ability to create strong, clean welds with minimal distortion. The process is known for its efficiency, making it ideal for both small-scale precision work and large-scale production.

1.Types of Laser Welding

Laser welding encompasses several modalities, each tailored to specific applications:

- Continuous Wave (CW) Laser Welding: This method employs a steady laser beam, suitable for deep penetration welds. It is often used in high-volume applications, offering higher welding speeds and is particularly effective for thicker materials. For instance, it is ideal for automotive components requiring robust joints.

- Pulsed Laser Welding: Characterized by millisecond-long pulses, this type is optimal for thin materials, such as razor blades or delicate electronic components. It results in lower porosity and reduced spatter, enhancing weld quality, though it may induce hot cracking in alloys like aluminum, necessitating careful parameter selection.

- Laser-Hybrid Welding: This approach integrates laser beam welding with arc welding, such as Gas Metal Arc Welding (GMAW). The laser enhances welding speed, while the arc supplies molten metal, improving fill and joint strength. It offers greater positioning flexibility, increased speed over GMAW alone, and reduced undercutting, making it suitable for complex assemblies.

- Remote Laser Beam Welding: In this technique, the laser beam is maneuvered along the weld seam using a laser scanner, with the robotic arm not following the seam. It provides higher speed and precision, particularly useful for intricate geometries, and is increasingly adopted in modern automated manufacturing lines.

2. Advantages of Laser Welding

Laser welding offers significant advantages, enhancing its adoption across industries:

- High Precision: The focused laser beam enables narrow, deep welds, ensuring clean and accurate joints, critical for precision engineering applications.

- Minimal Heat-Affected Zone (HAZ): The concentrated energy minimizes thermal distortion, preserving the mechanical properties of the base material, which is vital for delicate or heat-sensitive components.

- Versatility: It can weld a diverse range of materials, including carbon steels, high-strength low-alloy (HSLA) steels, stainless steel, aluminum, and titanium, and is capable of joining dissimilar metals, expanding design possibilities.

- High Welding Speeds: Facilitates rapid production rates, improving throughput in manufacturing environments, as noted in Laser Welding Process: A Detail Explained – WayKen.

- Reduced Distortion: Lower thermal stress compared to traditional methods like arc welding reduces warping, ensuring dimensional stability.

- Automation-Friendly: Easily integrated into robotic systems, it supports consistent, high-volume production, enhancing efficiency and reducing labor costs.

- No X-Rays or Vacuum Required: Unlike electron-beam welding, it operates in open air without generating harmful radiation, improving safety and accessibility, as highlighted in comparisons with EBW in Laser Beam Welding – ScienceDirect Topics.

These benefits are supported by industry insights, such as those found in What is Laser Welding and How Does It Work? – TWI, emphasizing its role in modern manufacturing.

Welding Simulation in Abaqus Using the DFLUX Fortran Subroutine

3. Mathematical Theory of Laser Welding

The theory behind laser welding involves understanding heat transfer and material behavior. Research suggests the heat conduction model, based on the Fourier-Biot equation, helps predict temperature distribution, while multiphysics models account for fluid flow and phase changes. These are often solved using Finite Element Method (FEM) software, with heat source models like Gaussian or double ellipsoidal improving accuracy.

Steps for Laser Welding Simulation in Abaqus

Simulating laser welding in Abaqus involves several key steps, based on industry-standard practices and recent tutorials:

1. Model Setup in Abaqus

- Create a 3D model of the components to be welded (e.g., plates or pipes).

- Use appropriate element types for thermal analysis, such as DC3D8 (8-node linear heat transfer brick elements).

- Ensure the mesh is fine enough to capture thermal gradients accurately near the weld zone but coarse enough to manage computational time. For example, finer meshes are crucial near the weld pool to capture steep thermal gradients, while coarser meshes can be used for regions farther away to optimize computational efficiency.

2. Define Material Properties

- Define temperature-dependent material properties for the work-piece material (e.g., stainless steel or titanium).

- Key properties include:

- Density

- Thermal conductivity

- Specific heat

- Thermal expansion

- Elastic properties

- Plastic properties

- These properties are critical for accurate thermal and structural analysis during heating and cooling phases.

- Example: For stainless steel (SA240), properties can be input as functions of temperature using Excel files or directly in Abaqus, ensuring the model reflects real-world material behavior under varying temperatures.

3. Heat Source Definition Using Fortran Subroutine

- Use the DFLUX subroutine to define a nonuniform heat flux representing the laser beam.

- Common heat source models for laser welding include:

- Gaussian Distribution: Represents a bell-shaped heat distribution, suitable for surface heating.

- Cylindrical Involution Normal (CIN): Accounts for volumetric heat input with depth, often used for deep penetration welding.

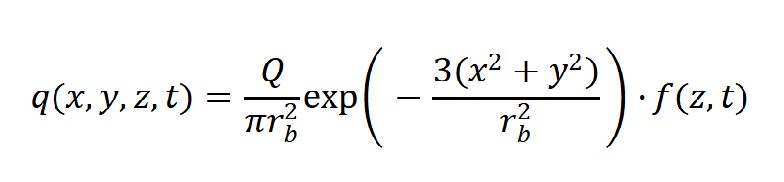

- The heat flux equation for a Gaussian laser beam can be expressed as:

where:

- (Q) is the total heat input (laser power),

- r_b

is the beam radius,

- (f(z,t)) accounts for depth and time dependence.

- In Abaqus, this is implemented via the DFLUX subroutine, which allows users to define custom heat flux distributions as functions of position and time.

4. Welding Path and Speed

- Define the laser beam’s path (e.g., linear for flat plates or circular for pipes).

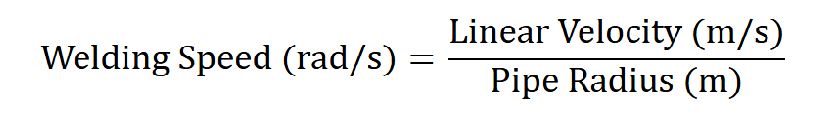

- Specify welding speed:

- For linear paths: Use mm/s.

- For circular paths: Convert linear velocity to rad/s using

5. Define Boundary Conditions in Abaqus

- Apply thermal boundary conditions:

- Convection: Use film conditions to model heat loss to the environment.

- Radiation: Optional for more accurate heat transfer, especially at high temperatures.

- Apply mechanical boundary conditions if performing coupled thermo-mechanical analysis (e.g., fixing supports to prevent rigid body motion), ensuring realistic simulation of structural behavior.

- Apply thermal boundary conditions:

6. Analysis Steps

- Set up coupled temperature-displacement steps:

- Welding Process: Simulate heating due to the laser beam (e.g., 6.283 seconds for one circular pass around a pipe).

- Cooling Process: Simulate cooling to room temperature (e.g., 1000 seconds), capturing residual stress development.

- Ensure time increments are small enough to capture rapid thermal changes during welding, typically in milliseconds for laser processes.

- Set up coupled temperature-displacement steps:

7. Running the Simulation

- Execute the simulation in Abaqus/Standard or Abaqus/Explicit, depending on the complexity of the model. Abaqus/Standard is typically used for static and quasi-static analyses, while Abaqus/Explicit is suitable for dynamic effects.

- Monitor for convergence issues and adjust mesh or time increments if necessary to ensure stability and accuracy.

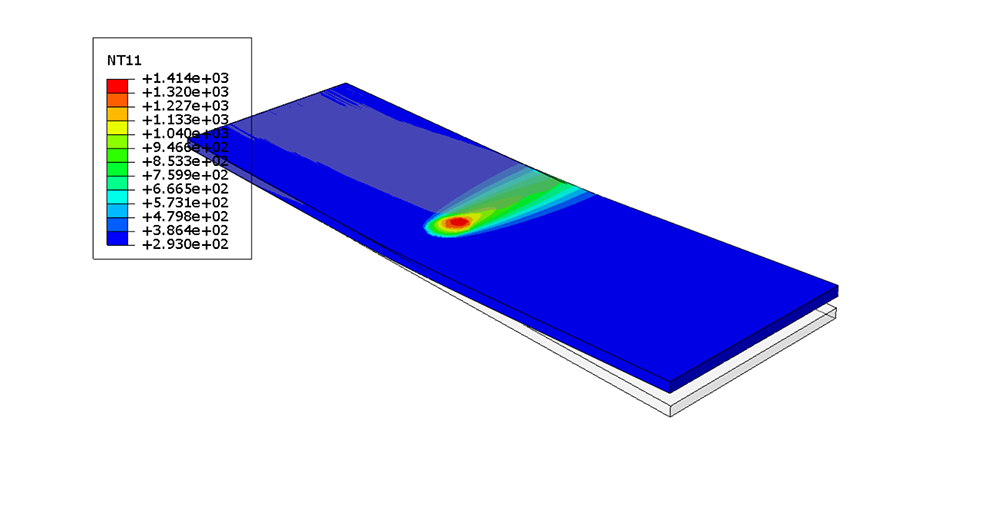

8. Post-processing and analysis of results

- Analyze results for:

- Temperature distribution during welding, visualized through contour plots.

- Stress fields and distortion post-welding, critical for assessing structural integrity.

- Residual stresses after cooling, which can affect long-term performance.

- Use history outputs to track temperature and stress evolution over time, aiding in parameter optimization.

- Validate simulation results against experimental data for accuracy, comparing weld bead geometry, thermal profiles, or residual stresses with physical tests.

- Analyze results for:

Resources

- Books:

- SpringerLink: Welding Simulations Using ABAQUS: A Practical Guide for Engineers provides comprehensive tutorials for professionals and students, authored by experts in mechanical engineering.

- Videos:

- YouTube: Laser Welding Simulation in Abaqus: Step-by-Step Guide demonstrates practical setup and analysis, with over 696 views as of recent updates.

- Plugins:

- Explore the Abaqus Welding Interface for streamlined weld model creation, as detailed in TECHNIA (UK): Abaqus Welding Interface.

- GitHub: welding_dflux_subroutine