A Comparative Analysis

Welding is a fundamental process in manufacturing, construction, and repair industries. Various welding methods are used depending on the application, material, and required precision. This article explores the most common welding techniques and compares their advantages, disadvantages, and applications.

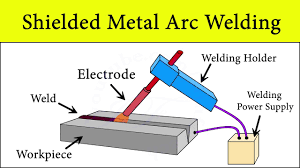

1. Shielded Metal Arc Welding (SMAW)

Also known as stick welding, SMAW uses a flux-coated electrode to create an arc between the electrode and the workpiece. The flux produces a shielding gas that protects the weld from atmospheric contamination.

Applications:

- Construction and infrastructure projects

- Shipbuilding and pipeline repairs

- Heavy equipment maintenance

Advantages:

- Suitable for outdoor and windy conditions

- Cost-effective and portable

- Works well on thick metals

Disadvantages:

- Requires skilled labor due to slag removal

- Produces significant spatter

- Limited for thin metals

Source: American Welding Society (AWS), “Introduction to Shielded Metal Arc Welding”

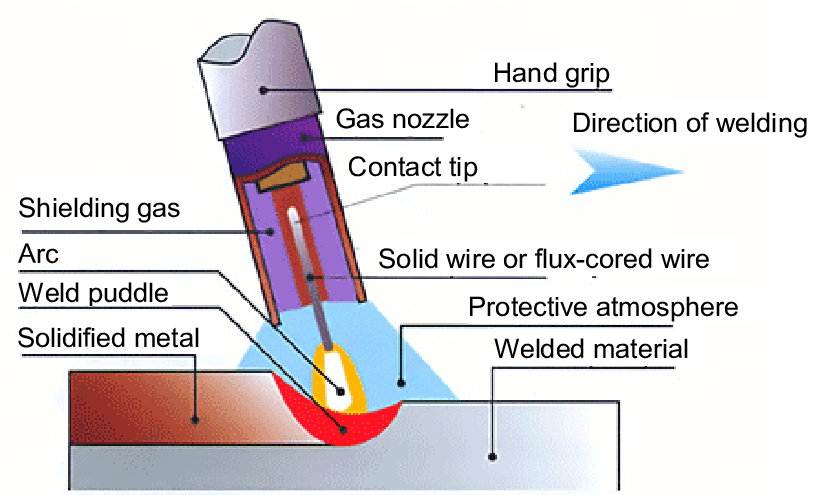

2. Gas Metal Arc Welding (GMAW/MIG)

GMAW, commonly known as MIG welding, employs a continuously fed wire electrode and shielding gas (such as argon or CO2) to protect the weld from oxidation.

Applications:

- Automotive industry

- Fabrication of stainless steel and aluminum components

- Home and DIY projects

Advantages:

- High-speed welding process

- Produces cleaner welds with minimal slag

- Easier to learn compared to SMAW

Disadvantages:

- Requires a clean work surface

- Not ideal for outdoor use due to gas shielding

- Higher equipment cost

Source: Lincoln Electric, “MIG Welding Basics and Applications”

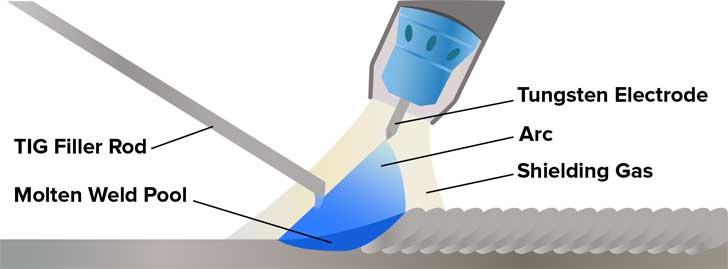

3. Gas Tungsten Arc Welding (GTAW/TIG)

GTAW, or TIG welding, uses a non-consumable tungsten electrode and an inert gas (typically argon) to create precise and high-quality welds.

Applications:

- Aerospace and precision engineering

- Welding of thin metals

- Ornamental and artistic metalwork

Advantages:

- Produces high-quality, precise welds

- No spatter or slag

- Works well with various metals

Disadvantages:

- Slower than other welding methods

- Requires a high skill level

- Expensive equipment

Source: Miller Welds, “TIG Welding Techniques and Best Practices”

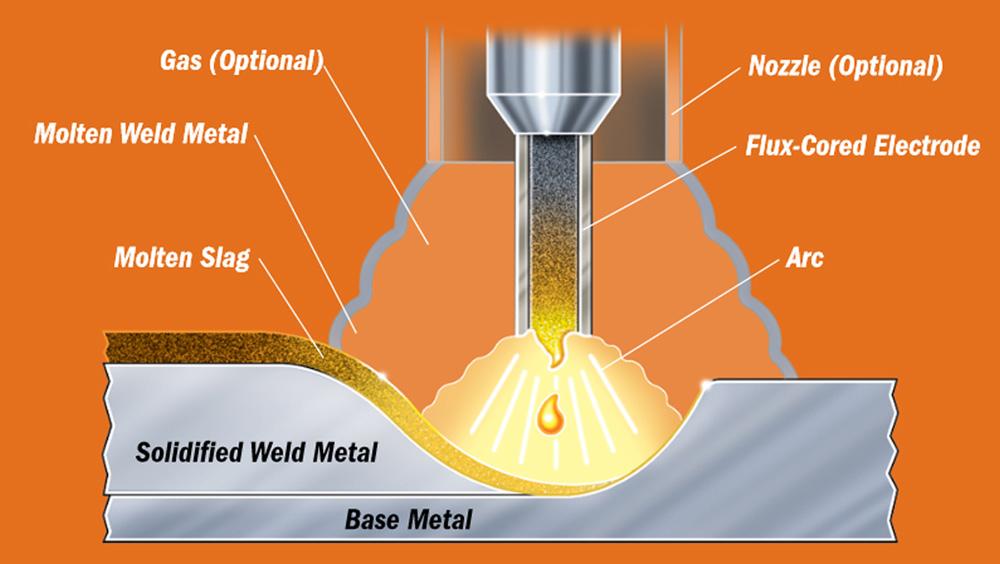

4. Flux-Cored Arc Welding (FCAW)

FCAW is similar to MIG welding but uses a tubular wire filled with flux, which eliminates the need for an external shielding gas.

Applications:

- Structural steel construction

- Heavy fabrication and shipbuilding

- Outdoor and windy environments

Advantages:

- High deposition rates

- Suitable for thick materials

- Effective in outdoor conditions

Disadvantages:

- Produces more fumes and slag

- Less precise than TIG welding

- Can be more expensive than SMAW

Source: ESAB, “Flux-Cored Welding Explained”

5. Submerged Arc Welding (SAW)

SAW involves feeding a continuous electrode beneath a blanket of granular flux, protecting the weld from contamination.

Applications:

- Large-scale industrial fabrication

- Pressure vessel and pipeline welding

- Structural welding

Advantages:

- Deep weld penetration

- High-speed and efficient process

- Minimal spatter and fumes

Disadvantages:

- Limited to horizontal or flat positions

- High initial equipment cost

- Not suitable for thin materials

Source: The Welding Institute (TWI), “Submerged Arc Welding: Principles and Applications”

Conclusion

Each welding method has its strengths and is best suited for specific applications. SMAW is a robust choice for fieldwork, while MIG and TIG welding offer precision for manufacturing. FCAW is a versatile option for heavy-duty applications, and SAW is ideal for industrial-scale welding. Choosing the right method depends on factors such as material type, environmental conditions, and required weld quality. Understanding these differences ensures efficient and high-quality welding results in various industries.