Welding is a critical process in manufacturing and construction, used to join materials, typically metals or thermoplastics, by causing coalescence. The process involves the application of heat, pressure, or both, and can significantly affect the material properties and structural integrity of the components being joined. Given the complexity of welding processes and their impact on material behavior, simulation tools like Abaqus have become indispensable for engineers and researchers. Abaqus, a powerful finite element analysis (FEA) software, offers robust capabilities for simulating welding processes, enabling the prediction of thermal, mechanical, and metallurgical responses.

This article delves into the various welding simulation methods available in Abaqus, exploring their theoretical foundations, practical applications, and the steps involved in setting up and running these simulations. By the end of this article, readers will have a comprehensive understanding of how to leverage Abaqus for welding simulations, ensuring accurate and reliable results.

Welding Processes and Their Challenges

Welding processes can be broadly categorized into fusion welding, solid-state welding, and brazing/soldering. Each category encompasses various techniques, such as arc welding, resistance welding, friction welding, and laser welding. Despite the diversity of welding methods, they all share common challenges, including:

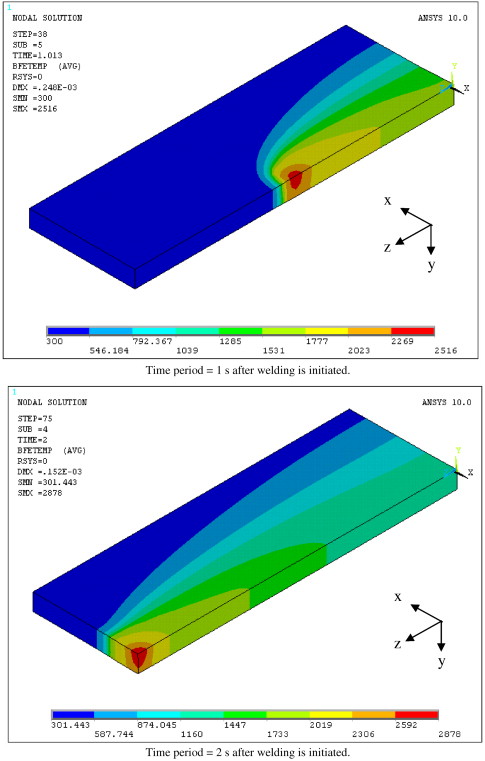

1. Thermal Effects: The localized heating and subsequent cooling during welding can induce significant thermal gradients, leading to residual stresses and distortions.

2. Mechanical Effects: The application of heat and pressure can alter the mechanical properties of the materials, affecting their strength, ductility, and toughness.

3. Metallurgical Effects: Phase transformations, grain growth, and the formation of microstructures such as martensite can occur, influencing the material’s performance.

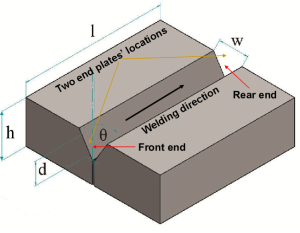

4. Geometric Complexity: The geometry of the weld joint, including the weld bead and heat-affected zone (HAZ), can be complex, requiring detailed modeling.

Finite Element Analysis in Welding Simulations

Finite Element Analysis (FEA) is a numerical method used to approximate the behavior of physical systems by dividing them into smaller, simpler elements. In the context of welding simulations, FEA allows for the prediction of thermal, mechanical, and metallurgical responses by solving the governing equations of heat transfer, solid mechanics, and phase transformations.

Abaqus, a leading FEA software, provides a comprehensive suite of tools for welding simulations. These tools enable the modeling of heat sources, thermal and mechanical boundary conditions, and material behavior, allowing for accurate predictions of welding-induced phenomena.

Different welding methods require different simulation methods.

1. Fundamental Principles of Welding Simulation

Welding simulation in Abaqus involves:

- Thermal Analysis: Modeling heat input, conduction, convection, and radiation.

- Mechanical Analysis: Predicting residual stresses, deformations, and phase changes.

- Coupled Thermo-Mechanical Analysis: Combining both thermal and mechanical effects for realistic results.

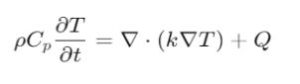

The governing equations include:

- Heat Transfer Equation:

where:- ρ\rho is the material density,

- CpC_p is the specific heat capacity,

- kk is the thermal conductivity,

- TT is temperature,

- QQ is the internal heat generation per unit volume.

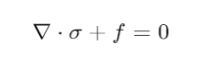

- Mechanical Equilibrium Equations:

where:- σ\sigma is the stress tensor,

- ff represents body forces.

2. Welding Simulation Methods in Abaqus

2.1. Sequentially Coupled Thermal-Mechanical Analysis

- Process: Solves the thermal analysis first, then applies the temperature field as a load in the mechanical analysis.

- Advantages:

- Less computationally expensive.

- Good for simpler welding scenarios.

- Limitations:

- No real-time interaction between thermal and mechanical effects.

- Cannot model phase transformations accurately.

2.2. Fully Coupled Thermo-Mechanical Analysis

- Process: Simultaneously solves thermal and mechanical equations.

- Advantages:

- More accurate for capturing real-time interactions.

- Essential for materials with significant thermal expansion effects.

- Limitations:

- Higher computational cost.

- More complex setup.

2.3. Element Birth and Death Method (Deactivation/Reactivation)

- Process: Simulates material deposition by activating elements at different time steps.

- Advantages:

- Models gradual material addition realistically.

- Captures heat-affected zone (HAZ) well.

- Limitations:

- Requires complex scripting.

- May cause convergence issues.

2.4. Moving Heat Source Method

- Process: Uses a heat source (Gaussian, double ellipsoidal) that moves along the welding path.

- Advantages:

- Realistic representation of moving welding arc.

- Works well with sequentially coupled analysis.

- Limitations:

- Requires precise heat source parameters.

- Complex calibration needed.

3. Comparison of Welding Simulation Methods

| Method | Accuracy | Computational Cost | Ease of Implementation | Best Used For |

|---|---|---|---|---|

| Sequentially Coupled Analysis | Medium | Low | Easy | Simple welding problems |

| Fully Coupled Analysis | High | High | Complex | High-precision applications |

| Element Birth and Death | High | Medium-High | Difficult | Additive manufacturing & multi-pass welding |

| Moving Heat Source | Medium-High | Medium | Moderate | Arc welding with moving sources |

4. Conclusion

Abaqus offers multiple methods for welding simulations, each with its own strengths and trade-offs. The choice of method depends on the complexity of the welding process, available computational resources, and required accuracy. While sequentially coupled analysis is computationally efficient, fully coupled analysis provides superior accuracy. The element birth and death method is effective for multi-pass welding, whereas the moving heat source method is ideal for capturing arc welding effects. Understanding these methods allows engineers to select the most appropriate approach for their specific welding applications.

This article provided an in-depth comparison of various welding simulation techniques in Abaqus. By leveraging these methods, engineers can optimize welding processes, minimize defects, and enhance structural integrity in welded components.