Abaqus is recognized as a premier finite element analysis (FEA) software. It enables engineers to simulate and solve complex physical challenges in industries such as automotive, biomedical engineering, civil engineering, and more. This comprehensive guide for beginners introduces the basics of Abaqus and explores its powerful toolset for structural, thermal, and multiphysics analysis. Along with a clear, step-by-step workflow, this article provides insight into key features such as advanced material modeling, nonlinear simulation, and real-world applications to get you started on your first project. Whether you are a student, researcher, or working engineer, this article provides the essential knowledge to start using Abaqus with confidence and exploit its full potential for engineering design and innovation.

Introduction: Solving Engineering Problems with Abaqus

Abaqus is a powerful engineering simulation software used by engineers worldwide. Developed by Dassault Systèmes, it helps solve complex mechanical problems through computer modeling. Imagine testing a bridge design without building it first – that’s what Abaqus enables. This complete beginner’s guide explains everything you need to start understanding finite element analysis software.

What is Finite Element Analysis (FEA)?

Finite Element Analysis is a computational method that breaks down complex objects into smaller, manageable pieces called elements. Think of it like slicing a cake into pieces to study each slice individually. Abaqus uses mathematical equations to predict how these elements behave under various conditions, helping engineers understand:

- Stress distribution in components

- Displacement and deformation patterns

- Thermal effects on structures

- Dynamic response to loads

A Brief History of Abaqus and Its Development

Abaqus began in 1978 as a university research project at Brown University. The name comes from the Greek word “abacus,” representing calculation. Key milestones include:

- 1978: First release for basic structural analysis

- 2005: Acquisition by Dassault Systèmes

- Present: Industry-leading simulation platform

Key Features and Capabilities of Abaqus Software

Comprehensive Physics Coverage

Abaqus handles multiple physics phenomena including:

- Structural mechanics

- Thermal analysis

- Fluid-structure interaction

- Electromagnetic effects

Advanced Material Modeling

The software includes sophisticated material models for:

- Metals and alloys

- Composites and plastics

- Rubber and polymers

- Concrete and soils

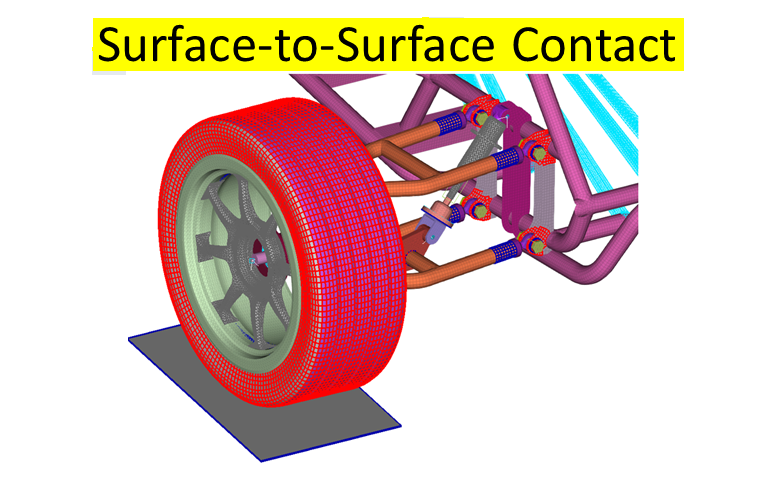

Powerful Contact Analysis

Abaqus excels at simulating interactions between multiple parts, automatically detecting and managing complex contact scenarios that occur in real-world assemblies.

Nonlinear Simulation Capabilities

Unlike basic FEA software, Abaqus specializes in nonlinear analysis involving:

- Large deformations

- Material nonlinearity

- Changing contact conditions

Abaqus Product Suite: Understanding the Components

Abaqus/CAE: The Complete Modeling Environment

Abaqus/CAE (Abaqus Complete Environment) is the central, integrated interface through which the entire simulation process is performed. It provides a seamless workflow from start to finish, integrating modules for part creation, material definition, assembly setup, stage configuration, meshing, job submission, and results visualization. Rather than working with multiple separate applications, engineers use Abaqus/CAE as a single interactive environment to build models, submit them to solvers such as Abaqus/Standard or Explicit, and then analyze the results through powerful visualization tools. This integrated approach makes it the essential interface for efficiently managing complex finite element analyses. Abaqus/CAE provides the user interface for:

- Creating geometry

- Defining material properties

- Setting up analyses

- Viewing results

Abaqus/Standard: Implicit Analysis Solver

Abaqus/Standard is the core implicit solver for solving static and low-speed dynamic engineering problems. It uses an iterative approach to find equilibrium solutions for each load increment. this feature making it ideal for analyses where inertia effects are negligible. This solver excels in handling nonlinearities from materials, large deformations, and complex contact conditions. Engineers rely on Abaqus/Standard for accurate stress analysis, heat transfer simulations, and pressure vessel assessments where solution stability is critical., ideal for:

- Structural stress analysis

- Heat transfer simulations

- Pressure vessel design

Abaqus/Explicit: Dynamic Analysis Solver

Abaqus/Explicit is a specialized dynamic analysis solver designed to simulate transient, high-speed events. Unlike the implicit method, the software uses a direct, incremental approach to solve complex problems involving rapid loading, impacts, and severe deformations. This makes Abaqus/Explicit an essential tool for simulating real-world scenarios such as vehicle crashes, drop tests, and manufacturing processes such as metal forming. Its robustness and efficiency in handling severe nonlinearities, complex contact, and material failure make Abaqus/Explicit essential for engineers in applications where inertial forces dominate the response of a structure. this solver excels at:

- Impact and crash analysis

- Drop testing

- Manufacturing processes

Industries and Applications Using Abaqus

Automotive Engineering Applications

The automotive industry relies heavily on Abaqus to develop safer, more efficient, and more reliable vehicles. Engineers use Abaqus to simulate and optimize virtually any component, from small brackets to complete vehicle systems. Key applications include crashworthiness analysis, where Abaqus/Explicit accurately predicts vehicle deformation and occupant protection during impacts, enabling manufacturers to meet stringent safety standards. The software is also critical for durability and fatigue evaluation, helping engineers predict component life under repeated loading conditions to prevent failure. In addition, Abaqus supports noise, vibration, and harshness (NVH) analysis to enhance passenger comfort and plays a critical role in optimizing lightweight designs through composite material modeling and topology optimization. These capabilities allow automotive companies to reduce physical testing costs while bringing higher quality vehicles to market faster.

- Crashworthiness simulation

- Noise and vibration analysis

- Component durability testing

Aerospace and Defense Applications

- Aircraft structural analysis

- Composite material design

- Satellite component testing

Civil and Structural Engineering

- Bridge and building design

- Earthquake simulation

- Foundation analysis

Biomedical and Healthcare Applications

- Medical implant design

- Bone stress analysis

- Surgical procedure simulation

Energy and Industrial Applications

- Turbine blade analysis

- Pressure vessel design

- Pipeline integrity assessment

Getting Started with Abaqus: Basic Workflow

Step 1: Creating Geometry and Parts

Start by building or importing your 3D model using Abaqus/CAE’s sketching tools or CAD import capabilities.

Step 2: Defining Material Properties

Assign material characteristics like Young’s modulus, density, and Poisson’s ratio to your components.

Step 3: Applying Loads and Boundary Conditions

Set up realistic operating conditions by adding forces, pressures, and constraints to your model.

Step 4: Meshing and Element Selection

Meshing and element selection are critical steps that directly determine the accuracy and efficiency of Abaqus simulations. This process involves dividing the complex geometry of a part into many small, simple shapes called elements, forming a “mesh”, then choosing appropriate element types for your analysis.

Step 5: Running Analysis and Viewing Results

Submit your job and visualize outcomes through contour plots, animations, and data reports.

Advantages of Using Abaqus for FEA

Accuracy and Reliability

The accuracy and reliability of Abaqus are why leading engineering firms trust it for critical design decisions. This trust is built on its robust, heavily validated solvers that produce results that consistently align with theoretical predictions and real-world experimental data. The software uses advanced algorithms to handle complex nonlinearities – such as large deformations, complex contact, and material plasticity- without introducing numerical instabilities. In addition, its extensive library of elements and complex material models enables highly realistic representations of physical behavior. This combination of proven numerical methods, comprehensive validation, and advanced modeling capabilities ensures that engineers can have high confidence in their simulation results, reducing the need for costly physical prototypes and reducing project risk.

Comprehensive Solution Capabilities

Abaqus offers comprehensive problem-solving capabilities and an unparalleled range of analysis types in a single, integrated environment. The software allows engineers to explore not only basic linear stress analysis, but also highly complex real-world multiphysics phenomena. This includes simulating fluid-structure interactions, modeling fully coupled thermal stress problems, analyzing advanced composite materials, and predicting the complex behavior of rubbers and polymers. Its comprehensiveness eliminates the need to master multiple specialized software packages and enables a seamless workflow from a simple static analysis to a complex dynamic event involving impact, heat, and material failure in one place. This makes Abaqus a versatile and powerful tool for virtually any engineering simulation challenge.

Industry Recognition and Acceptance

Widely adopted across major industries, Abaqus proficiency is a valuable skill for engineering professionals.

Learning Abaqus: Resources for Beginners

Official Documentation and Tutorials

Dassault Systèmes provides extensive documentation, example problems, and step-by-step guides.

Online Courses and Training

Many platforms offer structured Abaqus courses, from beginner to advanced levels.

Community Support and Forums

Active user communities and technical forums provide practical advice and troubleshooting help.

Frequently Asked Questions (FAQ) – About Abaqus

While Abaqus has advanced capabilities, beginners can start with basic features and gradually progress to complex analyses through structured learning.

Both are powerful FEA tools, but Abaqus typically excels in nonlinear analysis and complex contact problems, while ANSYS offers broader fluid dynamics capabilities.

Yes, Abaqus has extensive composite material modeling capabilities, including layered structures and advanced failure criteria.

Pricing varies based on modules and licensing options, with both annual leases and perpetual licenses available.

Abaqus requires substantial computational resources for optimal performance. For basic learning and small models, a computer with 16GB RAM, a multi-core processor, and dedicated graphics is sufficient. For professional use with large, complex models, we recommend 32GB+ RAM, high-frequency processors (Intel i7/i9 or AMD Ryzen 7/9), and professional-grade graphics cards. Solid-state drives (SSD) significantly improve simulation speed for file-intensive operations.

Conclusion: Your Next Steps in Learning Abaqus

Abaqus represents the gold standard in engineering simulation software. Its comprehensive capabilities and industry acceptance make it an essential tool for modern engineering. Start with basic tutorials, practice with simple models, and gradually tackle more complex simulations as you build confidence.

Start Your Abaqus Journey with Mathech Experts

- Personalized training sessions

- Project-based learning

- Professional simulation support