This comprehensive guide to welding simulation is based on our team’s practical experience comparing experimental welding results with numerical simulation. In addition to simply listing the steps involved in welding simulation, we provide clear and authoritative explanations of why each method works and how to apply it effectively. Our website covers how to use Abaqus and turn complex formulas into simple, reliable models.

In the following sections, we will not only compare the main welding simulation methods in Abaqus, but also explain in full detail the reasons for choosing each method.

Welcome to a clearer and more confident path to mastering welding simulation in Abaqus. Let’s get started.

Background and Importance of welding simulation

Welding simulations in Abaqus are important for predicting the effects of welding on parts. Some of the effects of welding heat, such as deformation, material distortion, and residual stresses, are very important. These simulations are especially valuable in complex welding scenarios that can be expensive or time-consuming to investigate using traditional experimental methods. Abaqus uses finite element methods (FEM) to model these processes, offering a range of approaches from detailed thermo-mechanical analyses to simple mechanical models. The choice of method depends on the specific simulation requirements, such as the need for accuracy, computational resources, and the scale of the structure being analyzed.

Types of Welding Simulation Methods in Abaqus

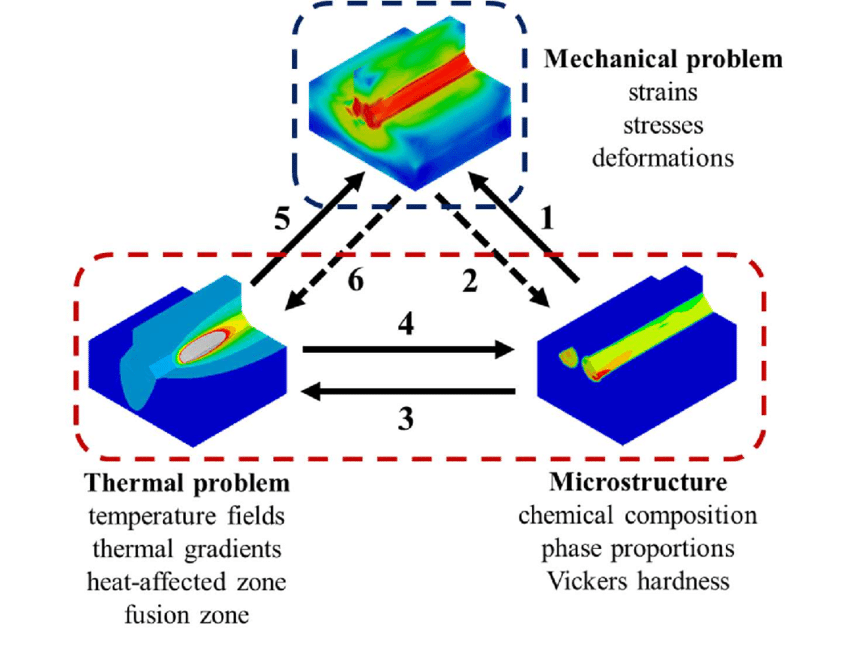

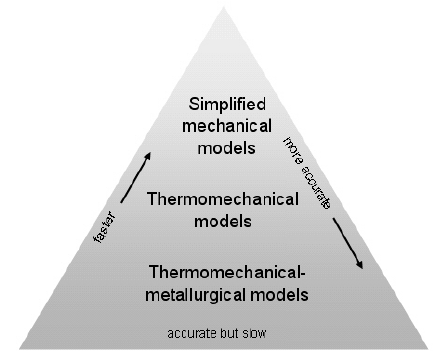

Based on recent studies, welding simulation methods in Abaqus can be classified into three main types: thermomechanical-metallurgical models, thermomechanical models, and simplified mechanical models. Each method has distinct characteristics, which are summarized below:

Thermomechanical-Metallurgical Models

- Description: These models account for temperature-dependent material properties, such as Young’s modulus and yield stress, as well as metallurgical changes during welding. They provide a comprehensive analysis of thermal distribution, material deformation, and residual stresses, making them suitable for detailed research.

- Implementation in Abaqus: Abaqus supports these models through coupled thermal-stress analyses, often requiring user-defined subroutines like DFLUX for custom heat flux distributions. The “death and birth of elements” method, where elements are activated or deactivated to simulate material addition, is also key, as noted in guides such as Abaqus Welding Simulation Complete Guide.

- Accuracy: High, particularly when detailed material data is available. However, accuracy can be uncertain if material properties are extrapolated, as highlighted in the review by Marques et al. (2020).

- Computation Time: Very high due to the complexity of solving coupled equations and the need for fine mesh resolutions.

- Applicability: Primarily for research purposes, especially in academic settings where understanding material behavior at a microscopic level is critical.

- Pros: Offers detailed insights into welding effects, including phase transformations and microstructural changes.

- Cons: Computationally intensive, requiring significant resources and extensive material data, which may not be available for all materials.

Thermomechanical Models

- Description: These models focus on the thermal and structural behavior of the material during welding, without necessarily accounting for metallurgical changes. They are less complex than thermomechanical-metallurgical models but still provide good insights into thermal distribution and structural deformation, particularly for distortion prediction.

- Implementation in Abaqus: Commonly implemented using sequentially coupled thermal-stress analysis, where a thermal analysis is performed first, followed by a structural analysis using the temperature results. The Abaqus Welding Interface (AWI), a freely available tool, simplifies this process by automating model setup, as discussed in Simulating Welding Using the Abaqus Welding Interface – Part 2. Features include automatic handling of model changes and simplified heat flux definitions.

- Accuracy: High for distortion prediction, but only average for stress levels, according to Marques et al. (2020). Studies show good agreement with experimental results, with errors typically in the 0-5% range for distortion.

- Computation Time: High, but less than thermomechanical-metallurgical models, making it more feasible for industrial applications.

- Applicability: Suitable for both research and industry, especially when the primary concern is distortion and structural behavior. It is widely used in sectors like automotive and aerospace for optimizing weld designs.

- Pros: Balances accuracy and efficiency, with tools like AWI reducing setup time. Efficient for predicting distortion, which is a major concern in industrial joining practices.

- Cons: Less detailed than thermomechanical-metallurgical models, particularly for stress analysis, and may require additional validation for complex welds.

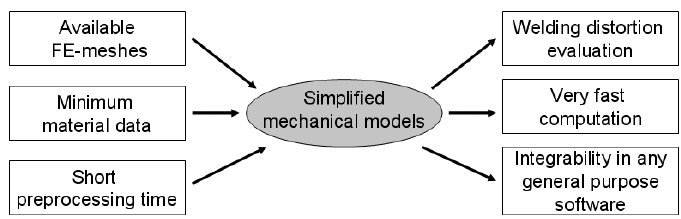

Simplified Mechanical Models

- Description: These models simplify the welding process by focusing on specific aspects, such as material shrinkage, initial stresses, or strains, to predict welding effects. They are less computationally intensive and are often used for quick assessments or large structures.

- Sub-Types:

- Thermal Shrinkage: Models material shrinkage at nodes, considering the welding sequence. It is a low-effort approach requiring minimal parameters.

- Prestressed Truss Element: Uses 1D elements to connect weld line nodes, focusing on longitudinal shrinkage mechanisms. It is fast and mesh quality is not critical.

- Initial Stress and Strain: Applies predefined stresses and strains to weld elements to simulate welding effects, accounting for distortion, plastic deformation, and stress state.

- Implementation in Abaqus: These can be implemented by defining initial conditions or using simplified element types in Abaqus, as supported by its flexible FEA framework. Guides like Arc Welding Abaqus Modeling provide examples, such as using DFLUX for heat source modeling.

- Accuracy: Moderate, generally good for distortion prediction but less accurate for detailed stress analysis. Errors can range from 11-17% for specific parameters like weld pool width, as noted in studies.

- Computation Time: Low, with examples showing computation times as low as 13 seconds for initial stress/strain models, compared to hours for more complex models like SYSWELD, as per Marques et al. (2020).

- Applicability: Useful for both research and industry, especially for large structures or when computational resources are limited. They are particularly effective for preliminary assessments or when detailed material data is unavailable.

- Pros: Fast and require minimal material data, making them accessible for quick simulations. Reduces analysis time by up to 70% in some cases, as seen in inherent strains methods.

- Cons: Less accurate for complex welding scenarios, particularly for residual stress prediction, and may not capture all thermal effects.

- Sub-Types:

Comparative Welding Analysis in Abaqus

To facilitate a clear comparison, the following table summarizes the key attributes of each method, based on the review by Marques et al. (2020) and practical guides:

| Method | Material Data | Computation Time | Accuracy | Applicability |

| Thermomechanical-Metallurgical | Temperature dependent, extensive data | Very High | High (if data available) | Research |

| Thermomechanical | No temperature data needed for some props | High | High for distortion, average for stress | Research & Industry |

| Simplified Mechanical | Minimal, e.g., shrinkage, initial stress | Low | Moderate | Research & Industry |

- Accuracy vs. Efficiency Trade-off: Thermomechanical-metallurgical models offer the highest accuracy but at the cost of very high computation time, making them less practical for industrial settings. Thermomechanical models, supported by AWI, strike a balance, offering good accuracy for distortion with manageable computation time. Simplified mechanical models are the fastest but sacrifice detail, with errors potentially reaching 11-17% for certain parameters, as seen in inherent strains methods.

- Software Features and Tools: Abaqus enhances usability through the Abaqus Welding Interface, which simplifies sequential thermal-stress analysis and model changes. This is particularly beneficial for thermomechanical models, reducing setup time and complexity. For example, the AWI automates the activation/deactivation of elements to simulate weld deposition, as noted in Simulating Welding Using the Abaqus Welding Interface – Part 2. Additionally, Abaqus supports various heat source models, such as 2D Gaussian, Double-Ellipsoidal (Goldak’s), and 3D-Gaussian Conical, which are essential for accurate thermal modeling, as discussed in Abaqus Welding Simulation Complete Guide.

- Error Analysis and Validation: Recent studies, such as Marques et al. (2020), indicate that FEM simulations in Abaqus typically have low errors compared to experimental results, with 21.05% of studies showing errors in the 0-5% range. Specific examples include FEM underestimating transverse residual stress by 7% and longitudinal by 2% for wide butt welds, as seen in cited works. This reliability makes Abaqus a trusted choice for welding simulations, particularly when validated against experimental data.

Practical Considerations and Recommendations for welding simulations in Abaqus

The choice of simulation method depends on the specific needs of the simulation:

- For Research-Oriented Simulations: Thermomechanical-metallurgical models are recommended when detailed insights into material behavior, including phase transformations, are required. However, they demand significant computational resources and extensive material data, which may limit their use in resource-constrained environments.

- For Industrial Applications: Thermomechanical models, often facilitated by the AWI, are ideal due to their balance of accuracy and efficiency. They are particularly effective for predicting distortion, a major concern in industrial joining practices, and can be set up quickly for production environments.

- For Quick Assessments or Large Structures: Simplified mechanical models are suitable, offering low computation time and minimal data requirements. They are effective for preliminary assessments or when analyzing large structures, reducing analysis time by up to 70% in some cases, as seen in inherent strains methods.

Unexpected Detail: Role of Heat Source Models

An unexpected aspect of welding simulations in Abaqus is the variety of heat source models available, such as 2D Gaussian for manual metal arc welding (MMAW), Double-Ellipsoidal (Goldak’s) for arc welding, and 3D-Gaussian Conical or Uniform Surface Heat Flux (USHF) for electron beam or laser welding. These models, while not always highlighted, significantly affect simulation accuracy, particularly for thermal distribution, and can be customized using subroutines like DFLUX, adding flexibility to the simulation process.

Here is Simulating Single-Pass Welding in Abaqus: A Practical Guide to Implementing the Birth and Death Method on a Flat Plate

Conclusion

Welding simulation methods in Abaqus offer a wide range of options, from detailed thermo-mechanical-metallurgical models for research to simplified mechanical models for rapid industrial evaluations. Thermomechanical models, supported by tools such as the Abaqus Welding Interface, provide a practical balance for most applications, with low (0-5%) errors compared to experiments. This comprehensive approach ensures that engineers can choose the method that best suits their needs and optimize welding processes in terms of safety, efficiency, and cost-effectiveness.

Key Citations

- Abaqus Welding Simulation Complete Guide

- Arc Welding Abaqus Modeling

- Comparison of Finite Element Methods in Fusion Welding Processes—A Review

- Simulating Welding Using the Abaqus Welding Interface – Part 2